Radial-Arm Drill Presses

Our exclusive online review examines two benchtop models that offer extra reach and tilting heads

When we set out to test benchtop drill presses, we combed the market for models that were in stock and still being manufactured. We also wanted larger models, ones that let you drill a hole at least 3 in. deep in one plunge. Nine standard benchtops met those criteria (read the review). So did three somewhat unconventional drill presses that let you do some things the others don’t. They’re called radials, because their drilling assemblies turn on an axis, like a hand on a clock.

When we set out to test benchtop drill presses, we combed the market for models that were in stock and still being manufactured. We also wanted larger models, ones that let you drill a hole at least 3 in. deep in one plunge. Nine standard benchtops met those criteria (read the review). So did three somewhat unconventional drill presses that let you do some things the others don’t. They’re called radials, because their drilling assemblies turn on an axis, like a hand on a clock.

Angled holes and more

This radial action means you don’t have to tilt the drill press table to make angled holes. The work piece stays horizontal, and the drill bit comes down at the angle. This comes in handy when you’re drilling holes in a long board that can’t be tilted far enough for the angle you need because the bench top gets in the way. It also makes jobs requiring lots of angled holes, like chair-making, a lot easier.

Radials have one other special feature: the shaft that serves as the drilling-assembly axis also can be pulled forward, typically by up to 17 inches, allowing you to drill a hole in the center of a work piece that’s up to 34 inches deep. That’s at least twice the capacity of any standard benchtop drill press. It also gives you one big advantage common to floor-standing models, the ability to drill into the end of a long work piece such as a table leg. And, since you can tilt the workpiece — all the way to horizontal, if necessary — even a bed post is fair game.

The other good news about benchtop radials is that, even with their extra capacities, they cost no more than standard models. Not bad, considering their performance in our tests. We gave the radials the same workout as the standard models, checking for drilling power, drilling capacity, and ease of use. They finished about in the center of the pack, higher than some non-radials in one or two tests, lower in others.

Two models tested

Two of the radials — the Grizzly G7945 and Shop Fox W1669 — are made by the same manufacturer and, on paper, are essentially the same machine. A third model from Rikon (model 30-140) arrived in the shop to late for our review. Both showed good drilling power, plunging a two-inch Forstner bit 3/4-in. deep into a maple board at a steady and relatively fast pace. From that point on, however, the Grizzly pulled ahead.

Although both models offer the same range of five speeds (550-3470 rpm), we found it easier to change speeds (by manually moving a belt from one set of pulleys to another) on the Grizzly than on the Shop Fox. The Grizzly drilled with far less runout (although the difference probably would not be noticeable in most drilling applications), and its square table is larger than the round one on the Shop Fox.

What to watch out for

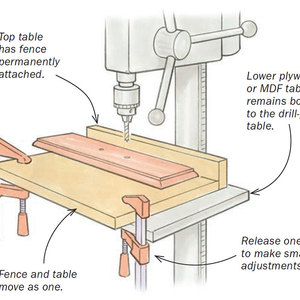

Radials do have some unavoidable drawbacks. Because they have more moving parts — chief among them is the rotating and sliding axis shaft — they need to be checked for square more often. They also need a more solid add-on table, preferably one that can be grounded on the bench top, to keep the work piece from flexing under the angled plunge. And they need more room than standard benchtop models to accommodate the long axis shaft that gives you that great, 17-inch throat capacity.

Photos: Matt Berger and Charlie Reina

Comments

Fifth paragraph - "[too] late for our review," not "to."

Wow) That's cool

Log in or create an account to post a comment.

Sign up Log in