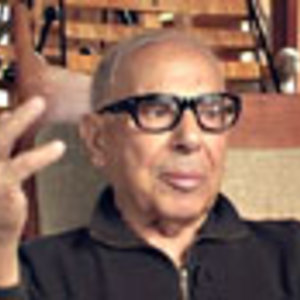

Sam Maloof on Building Chairs

In this excerpt from the book Designing and Building Chairs, the famed furniture maker details how he shapes the arms on his sculpted chairs

What do I use to shape the arm of a chair? The best tool for the job. I don’t get hung up on using all power tools or all hand tools. If you get too mechanized, you have to design around the capabilities of the machines, and your furniture won’t have the feel of handmade work. If you move to the other extreme and become a purist who won’t use power tools at all, well, that’s okay. But be prepared-you may starve to death. My philosophy is closer to Wharton Esherick’s. He once said to me, “I use any tool that’ll do the job. If I have to use my teeth, I use my teeth.”

I begin my chair arms by tracing a plan-view pattern on a 12/4 walnut board, flopping the pattern and nesting layouts to get as many arms as possible out of the piece. When I started woodworking, I used to cut out the arms of my chairs with a handsaw. I didn’t have any power tools back then. I bought a little keyhole saw, and I cut out chair arms with that. Then I used a drawknife and a spokeshave and a rasp to take it to its final shape. My technique now isn’t that different; the main thing is I use a bandsaw instead of a keyhole saw. And it’s a lot faster.

Shaping the arm

Shaping the arm

I do most of the shaping of chair arms freehand on the bandsaw. I can shape a pair of arms in about 15 minutes. It works well for me, but I do not recommend this method. It’s very dangerous because the workpiece is inadequately supported as you cut. The only reason I do it this way is that I didn’t know any better when I started. I’m very careful when I do it, but being careful doesn’t remove the danger. I have had a piece of wood slam down on my fingers and thought I had broken a finger or two. If I feel the blade grabbing, I take my hands off the piece of wood immediately and sacrifice the workpiece if I have to.

I have had people tell me they shape a chair’s arm with a router, following a pattern. I have never tried that. The only alternative I can advise is to use a keyhole saw, a drawknife, and a spokeshave — the way I did when I started out.

Once I have roughed out the arm on the bandsaw, I use a Surform® (Stanley® model No. 295). This tool does about the same job as a spokeshave — it can take off a lot of wood very quickly — but I can use it without worrying about grain direction. I’m not taking out a lot of wood with it; I’m mainly fairing the curves and straightening the lines I cut on the bandsaw. As soon as I buy a new Surform, I cut its handle off so that I can control it better. With the handle

Once I have roughed out the arm on the bandsaw, I use a Surform® (Stanley® model No. 295). This tool does about the same job as a spokeshave — it can take off a lot of wood very quickly — but I can use it without worrying about grain direction. I’m not taking out a lot of wood with it; I’m mainly fairing the curves and straightening the lines I cut on the bandsaw. As soon as I buy a new Surform, I cut its handle off so that I can control it better. With the handle

removed I can really feel the work and get into it.

The Surform cuts quickly, taking little, noodlelike shavings and leaving a rough surface. To clean up after it, I use a very coarse cabinetmaker’s rasp. I have a range of rasps, but typically I’ll use three rasps to finish an arm, perhaps starting with a Nicholson® No. 11, then using a No. 48 and finishing up with a No. 1. Depending on the contours I’m smoothing, I use both the flat and rounded sides of the rasps.

With the rasp work done, I go over the arm with a Japanese tool that is a cross between a Surform and a rasp. Called a saw rasp, it is made by Shinto and has a cutting surface that is comprised of sawblades in a waffle pattern. They are sold in coarse and fine and are available in the Japan Woodworker catalog.

With the rasp work done, I go over the arm with a Japanese tool that is a cross between a Surform and a rasp. Called a saw rasp, it is made by Shinto and has a cutting surface that is comprised of sawblades in a waffle pattern. They are sold in coarse and fine and are available in the Japan Woodworker catalog.

To do all of this hand-shaping, I hold the workpiece in a regular bench vise. I do have two old pattern maker’s vises, which work beautifully for clamping odd-shaped pieces. But I’m not doing production, so I just use the regular vise that is on the bench where I usually work.

|

Excerpted from Designing and Building Chairs, pp. 30-33. For a look at Maloof at work and to see how his furniture embodies his ideas on craft, design, and technique, you can preview our Sam Maloof — DVD. More on Sam Maloof Browse all Books and DVDs |

Photos: Jonathan Binzen

Fine Woodworking Recommended Products

Drafting Tools

Dividers

Sketchup Class

Log in or create an account to post a comment.

Sign up Log in