Smart Dust Collection for Your Bandsaw

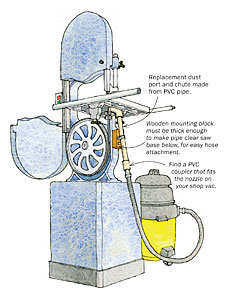

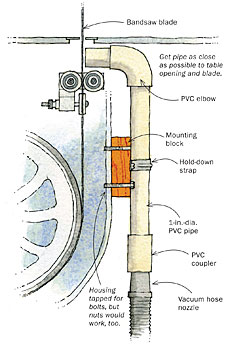

The bandsaw generates lots of dust and particles that, if not collected, are carried into the air or the lower wheel housing to build up and deposit on tires. Most bandsaws come with a dust-collection inlet located 4 to 6 in. below the table—too far away, in my view. For better results, I designed this shopmade inlet to sit just below the table and as close to the blade as possible.

To make it, you will need a length of 1-in.-dia. schedule 40 PVC pipe, some PVC fittings (at least a coupler and an elbow), and a wooden block for attaching the pipe to the saw.

The design of the lower wheel housing differs from saw to saw, so you will need to size and shape the block to fit yours. For my 14-in. cast-iron saw, I used a 3-in. by 5-in. block, 3⁄4 in. thick and grooved on the back to fit over a casting rib on the saw’s lower wheel housing. To attach the block, I drilled and tapped machine screw holes in the wheel housing. But you can leave the holes untapped and use a nut and bolt.

Next, put together the collection pipe with an elbow and a short length of PVC at the top to position the inlet as close to the blade and the underside of the table as possible. Don’t bother with cementing the pipe together. Try to match the coupler to the size of your vacuum nozzle. If needed, wrap tape around the nozzle to get a better fit.

Attach the PVC to the wooden block with hold-down straps from the front of the block. When tilting the table, you’ll likely need to remove the pipe and use the factory inlet instead.

Richard Babbitt, Friday Harbor, WA

Fine Woodworking Recommended Products

Shop Fox W1826

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in