All About Jointers

Rough lumber is just that — rough lumber. It often comes with dimensional distortions like twists and warps. A jointer corrects these problems and produces lumber that’s truly ready to be worked — straight, flat and square.

What Counts:

• Flatness and parallelism of tables

• Fence design and ease of operation

• Length of knives

• Overall length of tables

• Ease and accuracy of knife changes

How they work

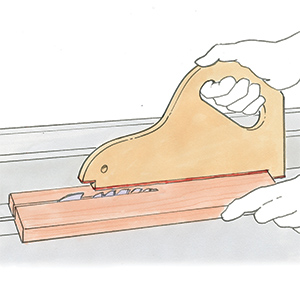

A jointer has both an infeed and an outfeed table, an adjustable fence, and a means of raising and lowering the infeed table to set the depth of cut. Knives are typically fixed in a rotating cutterhead that sits between the infeed and outfeed tables. Although these machines can be big and heavy, they also need to be precise. For the jointer to work properly, tables should be parallel and coplanar (that is, have no twist) as well as ground very flat. The fence also should be straight and flat.

Choosing by size

Jointers are sized by the length of their knives, which determines the widest possible board the machine can surface. Without any auxiliary extensions, a jointer can comfortably handle lumber about twice as long as the bed, so bed length, along with blade size, dictates the size of material the tool can process.

The smallest size useful to most woodworkers is the 6-in. jointer, which ranges in cost from about $300 to $750. One disadvantage of a 6-in. machine is that it can’t face joint (or flatten) stock any more than 6 in. wide. That means lumber that goes into wide surfaces, such as a tabletop, will have to be ripped down, jointed and then re-glued.

The next size up is an 8-in. jointer. These machines typically have longer beds as well as wider knives so they can handle wider and longer material. They also weigh more than 6-in. jointers, and the extra mass helps the tool to run more smoothly. But they also cost significantly more, with prices starting at more than $800 and typically costing several hundred dollars more than that.

There are larger machines still (industrial-sized machines have knives up to 16 in. long), but their cost, weight and size makes them a good fit for proportionally fewer woodshops.

Other features to consider

Other features that distinguish one machine from another are fence design and the height adjuster for the infeed table. Fence designs vary, but no matter what the type it should operate smoothly. Some fences can be adjusted with one hand, an advantage. Manufacturers use either wheels or levels to set the height of the infeed table. Both systems are effective, and both have their fans. On this issue, it’s probably a matter of personal preference.

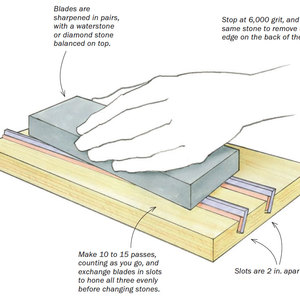

Most jointers use three knives whose height and alignment must be adjusted carefully if the machine is to operate properly. Jack screws, used on most machines, makes the process easier. Some jointers can be purchased with a spiral cutterhead that incorporates a number of small cutters that can be individually rotated if they become nicked or dull. These cutterheads add several hundred dollars to the cost of a jointer and can be purchased as an aftermarket add-on.

Fine Woodworking Recommended Products

Hedgehog featherboards

Veritas Precision Square

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in