All About Lathes

Lathes serve a variety of woodworkers, from those who work exclusively on miniature turnings like pen barrels and Christmas tree ornaments to bowl turners to furniture makers who need a lathe only occasionally for making a knobs for a cabinet or a set of table legs.

What Counts:

• Distance between centers on head and tail stock

• Maximum swing

• Power of drive motor

• Speed-control system

• Sturdy tool rest and vibration-free operation

Benchtop to bowl maker’s lathes

Lathes come in a variety of sizes and prices ranges to suit these different interests. Small benchtop models cost as little as $150, while heavy machines designed for lathe specialists and professional bowl makers easily top $5,000.

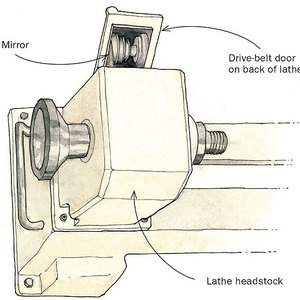

No matter what the size or sophistication of the machine, lathes share a number of characteristics. They consist of a motor that turns the work through the headstock, a set of rails that supports a tool rest and an adjustable tailstock that moves along the rails. Where lathes differ is in the size and power of the motor, the maximum length of work that can fit between head and tail stock, the maximum diameter of work that will fit between the headstock and the rails (called the “swing”), and the method used to control the turning speed of the work.

Spindle vs. faceplate turning

Turning falls into two broad categories — face turning and spindle turning — and the needs for each are slightly different. In faceplate-turning, a blank is mounted on a plate attached to the headstock. The tailstock isn’t used at all. Large, heavy or irregularly shaped pieces of wood require significant swing and low turning speeds. People who work exclusively on plates, bowls and other vessel-shaped objects don’t really need long rails and may want a lathe that allows turning really big objects on the outboard side of the machine, completely away from the rails.

In spindle-turning, however, both ends of the work piece need support so the distance between centers on the head and tail stock becomes crucial. Legs for a standard height table, for instance, must be about 29 in. long. Turning bedposts would require an even longer set of rails.

Choose your power

As size, power, and cost of a lathe increase, so does the power of the motor and the overall mass of the machine, which helps to dampen vibration. Higher end lathes also have more sophisticated speed-control systems, a key feature. The most basic requires the woodworker to move the drive belt to a different step on the pulley in the headstock. Better systems use a lever or wheel that alters speed while the lathe is running, while the best systems have electronic speed controls.

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Shop Fox W1826

Makita LS1219L Miter Saw

Log in or create an account to post a comment.

Sign up Log in