Door Essentials

Sort out design, construction, and hardware options when building doors for furniture

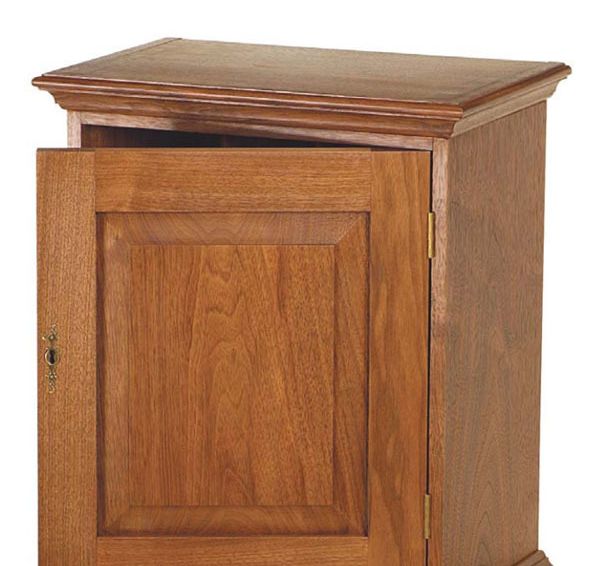

There are a number of design and construction options to consider when making doors for cabinets and other woodworking projects.

The Basics:

• Choose a method of construction: Frame-and-panel doors are the most common option.

• Not all doors must be seen: Pocket doors and tambour doors are two types that can stow away when opened.

• Going beyond flat: A bow-front door can be coopered, resawn, or laminated on a form.

• Add custom details: Handmade hardware and unique materials add personality to a project.

Choose a method of construction

Depending on the size of the door or the style of a piece of furniture, it is important to choose an appropriate construction method. Large doors benefit from frame-and-panel construction because it allows the panel to expand and contract in width from seasonal humidity without affecting the fit of the door on the piece of furniture. This is especially important if the door is inset into an opening.

There are several ways to vary the appearance of a frame-and-panel door. You can experiment with the width and placement of the stiles and rails (the top, bottom, and side members of the frame). Or you might build a more advanced frame-and-panel design, such as the tombstone door.

Not all doors must be seen

There are several methods to make stowaway doors on furniture, as seen in the tambour on 18th-century roll-top secretary desks, or the pocket door on modern-day entertainment centers. These are a good option if saving space is a concern. Tambours are constructed by gluing strips of wood to a canvas back. The flexible panel travels in grooves. Pocket doors can be hand built or use expensive hardware.

Go beyond flat

Coopering is a general woodworking technique that can be used for making bow-front cabinet doors. It involves assembling a panel from staves (strips of wood with beveled edges) and then shaping the joints smooth to reveal a curved form. Other techniques that will yield similar results include resawing a bow-front door from a thick piece of lumber and laminating thin panels on a form.

Add custom details

There is a variety of commercial hardware options for doors, but making your own knobs and pulls is a great way to personalize a project. Hand sculpted pulls can be as diverse as your imagination can take you, and turning pulls on the lathe is another a great way to add personality to a design.

Andy Rae is a furniture maker, teacher, and author of the book Building Doors and Drawers (Taunton Press, fall 2007).

Photos: Andy Rae

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Log in or create an account to post a comment.

Sign up Log in