All about clamping jigs

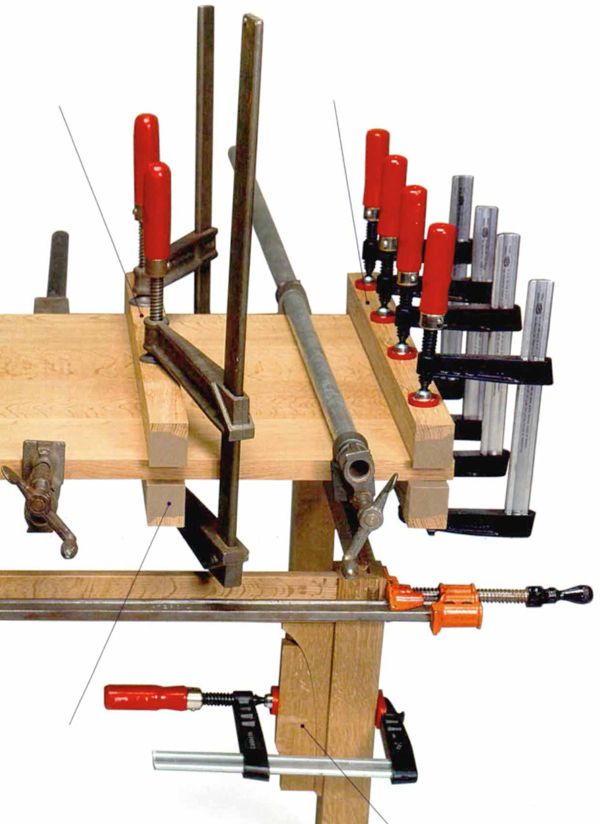

Store-bought clamps are fine for standard woodworking tasks like gluing up boards into a tabletop or assembling a drawer. But not everything you want to do is standard. When you’re faced with a non-standard woodworking task it is likely that the answer will come from a unique shop-built clamp or clamping aid.

The Basics:

• Shop-built clamping jigs solve unique problems.

• Incorporate commercial clamps, or create clamping pressure with shopmade parts.

Special shop-built clamping jigs can help you glue up a coopered door, laminate a complex curve, hold an odd-shaped workpiece for carving, or reach way across the soundboard of a guitar to glue on the bridge. In fact, if you can think of an application, a clamping jig can probably invented for it.

Gluing up picture frames is a common problem that seems to inspire many clever shop-made clamping solutions. Yes, commercial picture-framing clamps are available, but the shop-made solutions are better in many situations and certainly cheaper. We’ve seen picture-frame clamps that are based on a twisted cord, tapped wedges, special miter clamping blocks and spring clips.

Clamping jigs can incorporate commercial clamps in an unusual way or, more often, just use wedges, bolts or even car jacks for the clamping action. Woodworking catalog retailers sell a variety of clamping-jig accessories, such as cam clamps and toggle clamps, which are easily incorporated into shop-made jigs.

If your problem is just too few clamps, you can build shop-made clamps that are less expensive and just as good as the store-bought variety. Rest assured that if it moves and shouldn’t, there is a solution for clamping it down.

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Milescraft 4007 6in Bench Clamp

Incra Miter 1000HD

Log in or create an account to post a comment.

Sign up Log in