Do you work in a small shop? Tell us about it!

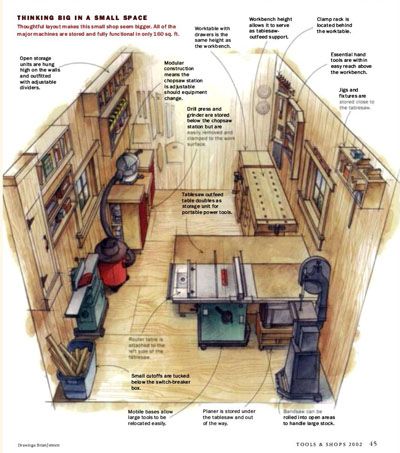

A small shop can be cozy, but how do you make the most of the space?

I’m trying to put together an article about small shops, and I could use your help. The focus of the article is not yet dialed in, but it could go in a few directions: It could become a profile of one or more shops, or it could become a compilation of great ideas for working in small spaces, like the basement shop article I wrote in 2009’s Tools & Shops issue (FWW #202).

Tour Some of Our Favorite Shops

When it comes to ingenuity, creative use of space, and just plain beauty–these shops really shine!

Chris Gouchner’s Garage Shop Expansion |

Mike Pekovich’s Ultimate Garage Shop Makeover |

John Tetreault’s Little Shop That Could |

Richard Ciupka’s Underground Dream Shop |

When I define small shops, I’m thinking of something the size of a one-car garage, or smaller, in the range of 200 square feet or so.

Basically, I’m looking for innovative ways to work in a small space. Here are some topics of interest:

Tooling

- What power tools can you fit?

- How did your tool choices affect your woodworking, or vice versa?

- How do you organize tools?

- Did you did you eliminate stationary tools altogether and opt for benchtop or handheld models?

- Have you opted for hand tools only?

Storage

- How do you store tools, both hand and power tools?

- Where do you keep lumber and supplies?

- How do you store clamps, long and short?

Workbenches and tables

- What kind of workbenches and worktables do you have?

- Did you design an innovative workbench that fits the space and is more versatile than a traditional bench?

Miscellaneous

- How do you handle dust?

- How do you get big stuff in or out?

- Do you have a unique way of lighting the space?

- How do you arrange power outlets?

- What’s your secret to working efficiently in the space?

- Do you finish in the space? If so, how do you handle harmful fumes?

These are just some ideas to get you started; but don’t feel limited by them. So tell me about your small shop, and send pictures of your unique way of working in it.

Email is quick and easy (tmckenna@taunton.com), but you can send stuff via snail mail, too:

Tom McKenna

Fine Woodworking

63 South Main St.

Newtown, CT 0647

Comments

Tom-

I'm sure this will yield a great article one day, however you have to admit that your basic premise is all wrong.

To ask "Do you work in a small shop?" is to ignore one of the most basic truths of woodworking.

Practically speaking you can never have too many clamps, tools, work surfaces, nifty jigs or pieces of amazing figured wood for that next project.

So clearly everyone must try to do what they can with what meager shop space they have been alotted in life.

I have a friend who is in a one-man shop of 5000 sq. ft. He has about every conceivable power tool and two cabinet saws -- one for ripping and one for cross-cutting. He and another friend in a "six car garage" (estimating 3200 sq. ft.) with a Euro saw are the only two I know that don't have space limitations.

My shop is a 12x12 foot corner room in my basement, which is pretty much the definition of a small shop. A table saw lives in the center, with workbenches, a bandsaw, a drill press, a smaller floor standing jointer, benchtop belt/disc sander, full sized router table, and combination planer-drum sander along the walls.

The planer-drum sander combo consists of a standard 13" planer and a homemade drum sander mounter on opposite sides of a rotating table top. When the planer is on the top and being used, the drum sander is hanging upside down.

There's also a dust collector in the corner, with the connected tools as close as possible to it. The table saw is connected using a 4" hose running on the floor which I've trained myself not to trip over. There's a air cleaner hanging above the workbench where I do my sanding.

If a project involves a full size sheet of plywood, I do as much as possible outside, which is easy due to a walk-out basement. Otherwise, I try to buy smaller sheets.

Overall, it's a real pain in the butt, but it's what I have so I make do. Generally speaking, I try to work on just one thing at a time, and move around slowly to keep from tripping on things.

I started out in a single car garage along with my wifes car. I had to move everything to one end every time she parked it. I found plans in the lumber yard for a gambrel roof so I build it 25x25 shop in my backyard. I thought it would always be big enough for my shop but if you put up a gym you will eventually fill it up.

Like Woodywrking, my shop is 12 X 12, I do have a 4X4 foot closet as well, and the space has to be shared with other, useful, homeowner needs - like lawn mowers, snowblowers, yard tools etc. I converted what used to be a screened-in patio on the corner of my rambler home to an enclosed space that opens into the back yard.

I'm certain my shop is not be a model for a magazine, if I had to wait for an acceptable work space I would not have a shop today. I view my small space primarily as safe, accessible, convienient storage and shelter for tools and projects. My work space allows me to work with smaller pieces indoors while the 6 foot rollup door opens up into the back yard to accomodate dimensioning larger pieces.

Wood storage is a combination of undimensioned lumber in my basement, limited storage in the shop, and disposal of scraps that would have a use if I had room to store them.

Dust management is accomplished by opening doors and windows into the outdoors. Finish work is either accomplished by moving into a basement, or cleaning the shop, and letting dust settle overnight. Most tools are portable or on wheels. Power tools wheel into the doorway and get moved out when ready for the next step. Tables are folding, jigs and storage hang from the walls, ceiling, and in an enclosed 7' cabinet. Electrical outlets are numerous, including some outdoors.

Woodworking outdoors is enjoyable, and I've been able to create 3 sets of kitchen cabinets for my home and rental properties as well as several other small projects.

My BIL has always had large shops. He looks at mine with envy when he can't find a tool in his large space. In my space, everything is within 3 steps.

One day, I will have that 26X26 backyard shop built, for now I am making what is available work.

Am relegated to a little less than half of a 2-car garage...my big space savings is a rolling workbench with built-in shelf storage underneath.

This is not a classic ww'ers bench, it's a basic work bench: a divided box on wheels with a work surface. The 36" X 72" top is an 1-1/2" thick glued-up slab of some tropical wood reused from a salvage kitchen table.

3/4" birch plwood was used for the base box construction. The floor is 1-3/8" thick from double sheets of ply glued and fastened together. A main ply divider runs down the middle of the unit, helps support the slab above and creates the two banks of 17-1/2" deep shelves on ea side for storage (equal to a 6' wide X 5-1/2' high shelving unit). The 2 solid end panels store screwdrivers, a few saws, squares, and other hangables.

It weighs perhaps 400 lbs or so when loaded down, so there's big 5" casters, (including a 5th caster centred underneath to prevent sagging)....can unlock and wheel around, yet is heavy enough that when locked down I would rely on for almost any work.

Overall height is set = same height as my table saw, so I use as an outfeed table for big stuff. I'm new to woodworking, will make drawers as soon as I get brave enough to try. The core idea was not mine - it came from a another ww'ing publication, but my end result was quite a bit different.

I started my “life” as a woodworker right out of high school in a tool shed in my parent’s back yard - Aprox. 9’ by 6’. I used this space for about a decade (even after moving out of my parent’s house, my father allowed me to keep the space since I lived in an apartment, and would come “home” on weekends to do work). I had a bench top band saw, a bench top jointer, a bench top sander, some hand tools (saws, planes, chisels, etc..), some hand power tools (drill, circular saw, etc..). Obviously, I had a small bench with storage beneath for the aforementioned tools, and a shelf on the back wall for wood storage. My only “stationary” power tool was the original “multi-machine”… a radial arm saw – a high school graduation present from my parents. I did EVERYTHING on it. You name it, crosscutting, ripping, jointing - boards too long for my table top jointer, planeing; I once turned a bowl on it using the motor as an outboard lathe with a jury rigged tool rest and hand made turning tool, and even used it as a pin router to make some marble games. NOTHING was precise on it, and so every project required “finishing” up with hand tools, but I think that I am a better woodworker today as a result. Sheet goods obviously were not an option, and so I could only work with sheet goods on nice summer days when I would drag the saw out into the yard. Boards longer than a couple of feet had to be fed in through the door, and out through the window. I cried when the parents sold the house and the shed was torn down by the new owners – time relentlessly marches on.

Today I work in a 1 ½ car garage, and when I first moved in I thought that I was in woodworker’s Heaven, but with adequate tool storage under a build in bench and cabinets, Robland x-31, air compressor, dust collector, and yes I still have the Radial Arm Saw, I now find myself in the same dilemma as millions of woodworkers before me… I just found a lathe that I simply could not walk away from, and have to decide whether to house the lathe out in the backyard shed, or store the sheet goods there (and the yard tools will need to find a new home), because I have run out of wall space… it appears that as with many before me, in my quest to make my woodworking life easier, I have grown to the point where I have come full-circle. To be honest, writing this I just realized that I make no more projects per year in my new(er) shop than I did in the old shed (and only the recipients of those projects could ascertain as to whether my larger shop has improved the quality), although I must admit that it’s nice to be able to work without having to first empty half of the shed into the yard.. but at the end of the day maybe mom was right… “less may or may not be more, but in the end all that one really 'NEEDS' sits comfortably inside of his skull”

My workshop is actually an 11 by 15 corner of the basement. I've had to compromise a bit. I use a contractor tablesaw, a benchtop bandsaw, and a benchtop router table. I have a full sized drill press, a full size planer, a full sized scroll saw, and a full size sanding machine. I double the planer as a jointer, and have a collapsable stand for my compound miter saw. I also have two "tops" I place on top of my table saw so it can double as a workbench or glue up station. I have built several shelves for storage, and an extantion for the table saw if needed. I use jigs when I can and store them on pipes above my work area.

Dust collection is a serious problem, I do have a dust collection port on the planer, and it hooks up to my shop vac. as for the rest, I simply clean frequently. I have another area in the basement I use for staining (a table near our washer) As for assembly, if I'm making furniture, assemble may have to take place elsewhere since I don't habe the space in shop and some items would be impossible to get up the stairs if assembled. a good example would be my computer desk which is about six feet wide and about 28" deep. I had to build it using Krieg screws. That way I could bring the individual pieces to my office and assemble "on site" since it was far too big to assemble in my shop and impossible to carry out once assembled.

Thanks for all the feedback, folks. I'm still poring through all the responses. More to come...

I am currently using my back porch, which is not enclosed, as a workshop. My wife and I are renting from my parents right now, therefore, I am not going to add to a house that isn't mine. So here goes.

Size of area: About 10' wide and 40' long, give or take two or three feet on the length.

This back porch actually serves as a visiting/bar-b-queing/welding/woodworking/playground area. Before i start on the tools, i will explain. A round iron table, four chairs, two bbq pits (one propane, one charcoal), two fish fry setups, and several ice chests. I have managed to put up a pvc material picket fence around the porch to keep the dogs out and my 2 year old daughter in.

As far as tools go I have built a workbench and installed an open air basic shelf below the bench-top. At this point i have cut a whole in the top of my workbench, made a router table insert, built a router-table style fence and am able to use the main workbench as a routing station. If i want to use it for assembly, i just take out the screws and remove the fence, lower the router bit and am good to go.

The workbench also has holes drilled in either end to mount my small bench-top drill press and bandsaw when needed.

I have a Craftsman 10" tablesaw which I like as far as size and portability, i wish i had gone with a different name brand but that's another story...

Opposite the workbench (up against the brick wall of the house) i have a separate workbench with peg boarded front sides, and an open ended storage rack for lumber.

The runners for the future ceiling are currently being used as a clamp rack, you'd be surprized how well Bessey bar clamps hang when positioned just right...

Anything else i get i do my best to buy power hand tools that come with a case.

I could definitely keep going for a while but I feel that I have said too much already.

Thanks for hearing me out!

- James

I started woodworking at the age of 10 sitting on the floor of the boiler room and shaping small pieces of wood with a cinder block as my bench. That got me hooked. When I was 15, we moved to a house with a basement that I set up a shop in a 10x10 corner of. I had an 8" craftsman tabletop saw (which is still kicking around at my brothers house 30 years later!), and a 3 wheel tabletop band saw that would never track properly. I also had a drill and a few sanders. My bench was a little 4 footer that we had in the shed in the last house (it too is at my brothers house now). I did a little whittling in that shop and made some furniture too. I built a gun cabinet that I still have today.

"The Woodwright's Shop" was on TV and I was so impressed with hand and leg powered tools that I started to build a treadle lathe (never got it finished but my design was good). Then, at the age of 18, my father told me I could use the 2 car garage that was just filled with junk as a shop! Holy Crap! I went nuts setting that place up.

I ran several electric circuits and 16 outlets around the place including 220 for welding (outside only). I went to the tool store one new years eve day with a loan from my father and had a ball. I bought a 10" contractors saw, 14" bandsaw, tabletop drill press, 10" miter saw, and scrollsaw, all Delta and all of which I still have except the miter saw. I bought more tools as time went by and reconfigured that shop many times over the next 16 years. (my parents divorced over that time and I stayed in the house and kept up the payments on it) I found an old Yates American lathe in a used tool store and had to have it. I got a used radial arm saw and a small compressor which I hung from the 10 foot high ceiling on a chained shelf. I built a basic bench which was also my outfeed table and bent and attched pipes to the wall for a vertical sheet goods storage rack. I also used that 10x10 area in the basement for a lathe room. It was woodworking bliss. I built a lot of stuff in that shop and learned a tremendous amount about woodworking there. (Thats where I started my home improvement company).

Then, as fate would have it, my father, who was still living there with me, passed away. It was always assumed that I would get the house but that never happened. My mother decided she didn't want the house anymore and I couldn't afford to buy it right then (business was slow and the economy had just start to fall), so it was sold. I bought an 18' enclosed trailer and packed my shop into it. I also bought a 12' box truck with cabinets on the sides to replace my old Chevy van for work. The new truck could hold a lot more tools and I would need to use it as a mobile shop now. The trailer got moved from place to place in storage since I rented an apartment with no room to park it and no shop space at all. I set up shop in the yard from the truck when I needed to build something. This went on for 6 years until I moved into a place with a seperate 11x27 garage that I was going to use for a shop. Turns out the building was steel sheathed in wood and weeped water all over rusting the few tools I put in there in the first week. Without a good solution to the problem, the shop never got set up and I remained shopless for another year.

Now, I have rented a house with a one car garage and have finally brought my trailer back to me and parked it next to the garage. I am very limited on power in the house with a 100amp service and 2 households in the place (my wife and I upstairs and my inlaws downstairs in the high ranch). I have the landlords permission and am going to run a 60amp subpanel for the shop and set the place up as best I can. I forgot to mention that just before the house was sold, I bought an Oneida dust collector that I had just built a metal stand for and was about to buy ducting for when it had to get packed away in the trailer. I had also just built a nice bench with cabinets below and a top made of a 6' piece of a shuffelboard table that was being cut up and discarded. I had bought a 1940s Walker Turner lathe that I had pieces machined for and rebuilt and a standing belt/disc sander. All of which was stored in the trailer.

I am about to embark on the adventure of trying to set up shop in a 9x23 garage with a 3x12 "closet" thats behind the second garage door which is screwed shut. (they built a bedroom in half of the garage and stopped 3' short of the second door. That area will become lumber storage which will be very much needed since there won't be any extra room in the shop for that. I will have the trailer next to the garage for storage of little used tools, materials and projects as they are completed before delivery. That too will be very handy to have. I can't wait to get started and this whole idea of a small shop story will be a great help.

I have seen tiny. I have seen portable, and I have seen fullly equipped. Now its time to take bits of all of those shops and make one that would be considered small. I know some of my big tools will have to go or stay in the trailer, but I hope I can put that dust collector outside the shop and duct it in.

Sorry about being long winded here, but this is a story I just wanted to tell someone, and this seemed like the perfect place for it.

This still an active blog? I'm currently moving from my garage to a under 200 sft outbuilding, starting from scratch, so it is definitely a subject of interest to me.

Log in or create an account to post a comment.

Sign up Log in