Dovetails are used all over the place in woodworking, but for newbies like me, they’re intimidating to cut. Perhaps the biggest reason is that any mistakes are so easily visible. When dovetails are miscut, it’s obvious. Learning to cut dovetails, for me at least, means learning to fix my mistakes. Like the one I just made.

It happened last week while I was working on a lunch time project here at FWW. I’m building the tapered leg Shaker side table from Christian Becksvoort’s article in FWW 210. The plans call for a dovetailed top rail on the front of the nightstand. I had already cut the tails when I decided to try cutting the socket entirely by hand, rather than with a router, which Becksvoort advises.

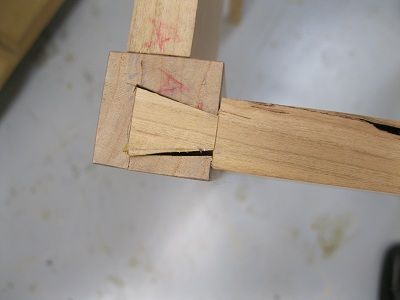

In hindsight, I should have used clamps to bolster the sides of the legs. After a few quick taps with a chisel, the leg started to split. I panicked, grabbed the router and began cleaning up the rest of the socket with it. In all the confusion, I ended up overcutting the socket, which left sizable gaps on either side of the tail.

I glued up the base, left for the long weekend, and decided to come back in today and fix my very obvious error. Since the rail will be concealed by the table top, I wasn’t worried about the aesthetics of my ugly joint. But I did want the rail to be secure, especially since I had made a hairline split in the front of the leg.

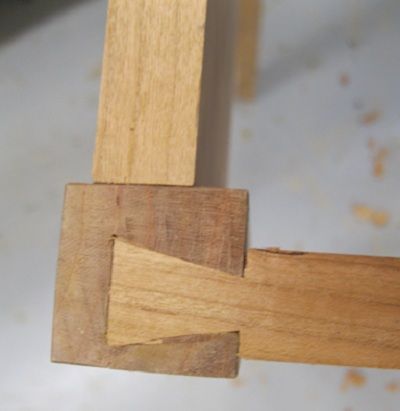

I decided to try fixing it using wedges cut from the end grain of the same boards, a technique that Phil Lowe covered back in FWW 186. I used a chisel to cut the wedges and then glued them in place. Thankfully, I had left the dovetails a little proud, so after the wedges dried, I used a block plane to flatten the surface and bring the rail flush with the top of the legs. It’s not as pretty as I would like, but it should be strong enough to hold the base together without any problems.

Comments

Great fix. Hope you don't give up on hand cutting out the waste. You have so much more control by hand. Just have to be careful to orient the chisel across the grain.

all craftsmen make mistakes. Master craftsmen know how to fix them! Good repair!

I think there are two issues, one aesthetic and one structural. As you point out, the aesthetic one is not important here. To maximize the structural support, I think you want the wedges to be the least wedge-like you can manage. In essence you want long straight shims so the entirety of the joint is filled, not just the top. With wedges, the top of the dovetail is fixed, but the lower part of the joint is still going to be loose. I think this is where one adds "DAMHIK".

Dovetail Joints are definitly not my stong point either. Good job, I'm pretty sure I will need to use this technique in the future :)

Nice fix. I recently split an end table leg at that same spot myself while chopping out the socket. Although I have high regard for Christian Becksvoort, the proportions for the dovetail here (https://www.finewoodworking.com/pages/w00078.asp) seem a bit more in "balance", looking at the different modes of possible failure of both mating pieces.

It just be be the photograph and the angle, but it looks to me that the top of the leg isn't square...even with the nice repair...are the reveals the same across the front of the case?

Just read the FWW reference article - thanks for that, and I think the repair looks great.

Log in or create an account to post a comment.

Sign up Log in