One Big Jointer: One Huge Upgrade

You might have seen my colleague Matt Kenney’s recent post about the work he put into his new Oliver 12 in. jointer.

But of course Matt is not the only one with room for an aircraft carrier in his shop. Oregon woodworker Frank Howarth, who also likes him some vintage iron, shot and edited this beautifully detailed video highlighting the work he’s put into his own turn-of-the-twentieth-century jointer from Porter.

Howarth walks through the history of the machine, its operation and recent modifications – a modern helical cutterhead and improved dust collection. He also shows the viewer, step by step, how he made a replacement for the missing cutter guard.

Mr. Howarth has an impressive shop and he knows how to put together an engaging video. Definitely worth a look.

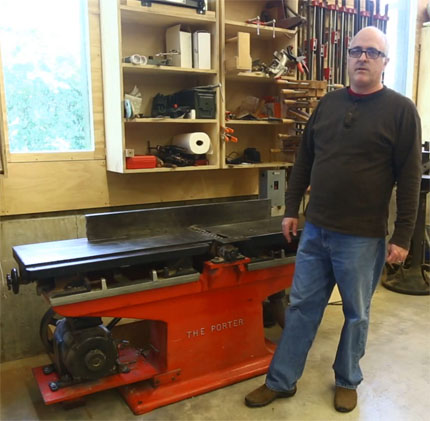

Frank Howarth bought and rehabilitated this 12-in. jointer which dates to the early 20th century.

Comments

That is Awsome.

This is great.

You really did a nice job - very informative. I was also fascinated with your shop setup in the background of your video, and pleased that there was a link to your website that not only gave a shop tour, but also a shop construction video and even a floor plan. I thought those videos were every bit as good and really got a lot out of them. Thank you!

Your excellent video was a great demonstration of the basic quality of a very old machine with a a lot of very smart design details, and a lot of ingenuity on your part to extend it's life. I can imagine that the designers of such wonderful tools would have been today's rocket scientists had they been born in the 20th century.

That was really great, in content and entertainment value.

The Stop Motion animation is wonderfully used. Great job. Good to see old iron back in use.

Great video. What a simple, elegant design. I've been fighting my newer Powermatic jointer, hard to adjust and access things. Newer is definitely not better.

Lovely use of an old machine! Great animation, Dare I ask - how much was the custom made cutting block?

good job

Really great example of extending an antique woodworking machine's usefulness into the 21st century and a well done video.This shows you can have both antique machines and modern features. I can tell by your shop that you really appreciate old machines.

What I found interesting was the design of the original guard. It is a bit more complicated but does use a lot less space, I've never seen this design before.

Great restoration. Two comments. A decent machine shop could replicate the infeed table end where the accidental blade missile knocked a piece out. Two, I would look online and try to find either a weight from a chain drive wind up clock. Or, an old Avery weight for a set of scales.

The shape of either would look just like the original. Most of the old weights were made out of brass.

I just love old machinery being brought back to life again. Thanks for sharing.

I'm jealous of your equipment. But I haven't the shop space for a monster like that. For another project I was looking at constant torque (constant force) springs, a coiled flat spring that would provide constant return force and eliminate the weight. It also seems to me that an appropriate curve along the back of the pork chop guard would keep it from sticking out from the bed so far when material is pushed through. You seem to have to walk a long way around the guard while holding the work in that last scene.

What a wonderful recycling of ole iron! A competent welder can easily repair the broken out portion of your infeed table without distorting the table. Your belt guard is an easy fix out of wood and sheet metal with your talents! I really like your shop and how much ole iron is in it as well as how neat you keep it.

Log in or create an account to post a comment.

Sign up Log in