Break Out the Hand Tools

Sometimes hand tools cut the joint faster and easier than machines or power tools.

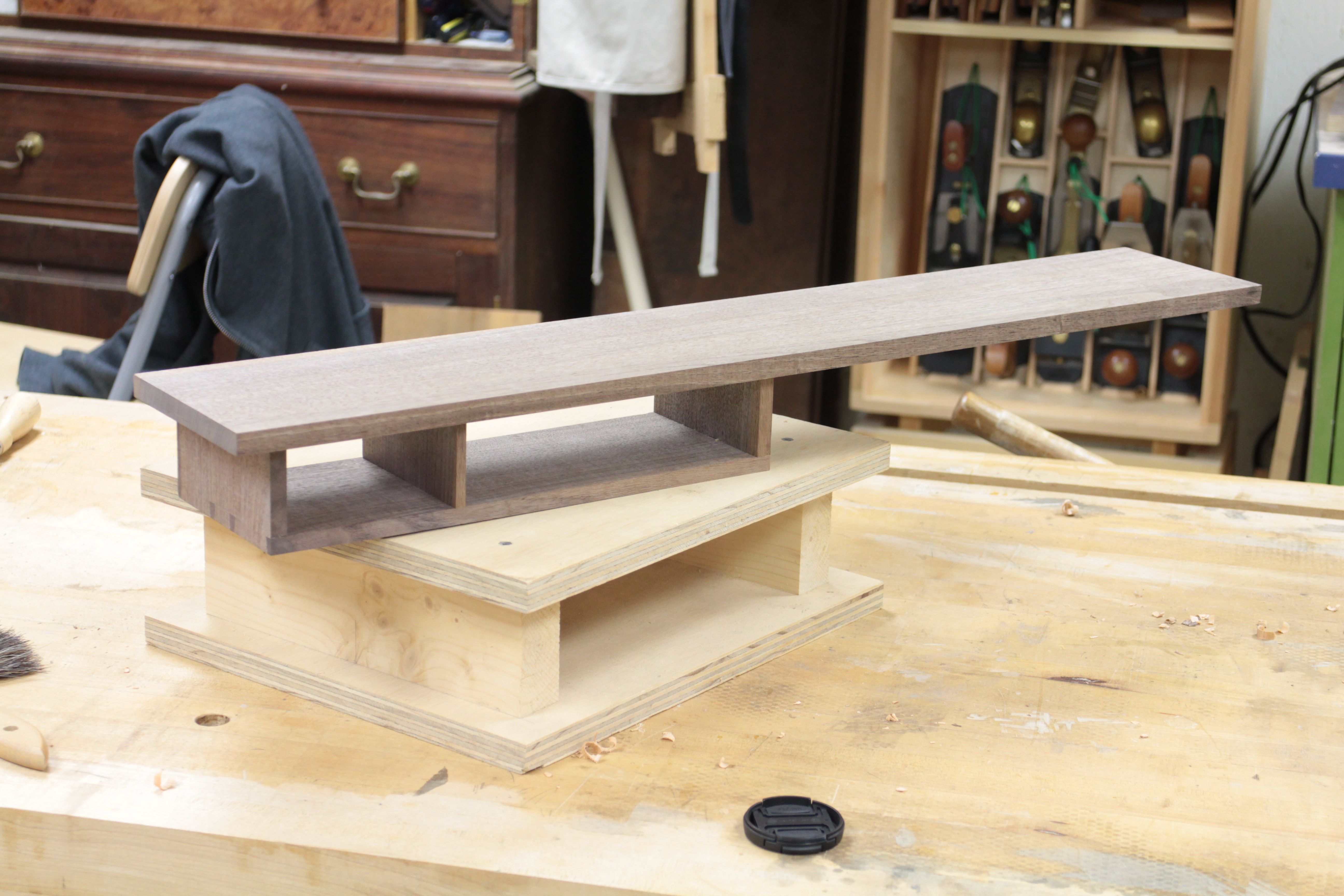

Small piece? Break out the hand tools. This little shelf with drawers is a perfect example of when to use hand tools. There is so little joinery that you won't gain much time by using machinery and power tools.

Like many woodworkers, I love tools and enjoy talking about them. I truly enjoy listening to someone talk about his favorite tool, and the joy he gets from using it. But there are some conversations about tools I avoid. I’d rather not debate whether new machines and hand tools are as good as the old ones. And I don’t care if some random, anonymous person on the internet thinks this or that hand plane or that router costs too much (actually, I don’t even care what someone I know thinks about that). But the conversation about tools that I find the least interesting and productive is the one where folks identify themselves as either hand tool or power tool guys and then argue the superiority of their side. If I were forced to answer this question myself, I’d say that I’m neither a hand tool nor a power tool guy. I’m a furniture maker. And the tools in my shop are just that, tools.

If your true interest in woodworking is to make furniture, you should learn to use machines, power tools, and hand tools. They all require skill and practice to master. And with a larger arsenal of tools at your disposal, there will be fewer limits on the furniture you can make. You’ll also be able to work smarter and more efficiently, always able to choose the tool and technique that enables you to get a particular task done accurately, quickly, and with the least frustration.

There are many cliché examples I could give you in support of my point. It’s true that you can’t beat a jointer, planer, and bandsaw for milling stock. And no random orbit sander can prep a surface quicker or better than a well-tuned smoothing plane. Instead, I’ll tell you about a small piece of furniture I’m making and some dadoes that needed to be cut. You can see the (not completed) piece in the photo above. It’s a shelf with a two small drawers beneath it. The dadoes in question are the ones for the vertical divider between the drawers. They are 1/8 in. wide and 3/16 in. deep. I often cut small, stopped dadoes like these at my router table. Here’s a blog about how I do that. The router table technique works so well, because you use a single fence setting to rout both dadoes. And this is possible because the dadoes are equidistant from the ends of the case sides.

However, the router table technique would be a huge pain in this case, because the shelf overhangs drawers. The dado in the underside of the shelf is further from the end than the dado in the top side of the drawer pocket bottom. To use the router table, I’d either have to move the fence between cuts (and that would almost certainly result in dadoes that were not aligned correctly), or make a shim. The shim would go between the fence and the drawer pocket bottom. But getting the shim the exact right width would be a tedious job, requiring lots of tests cuts and involving plenty of frustration. So, the router table was out.

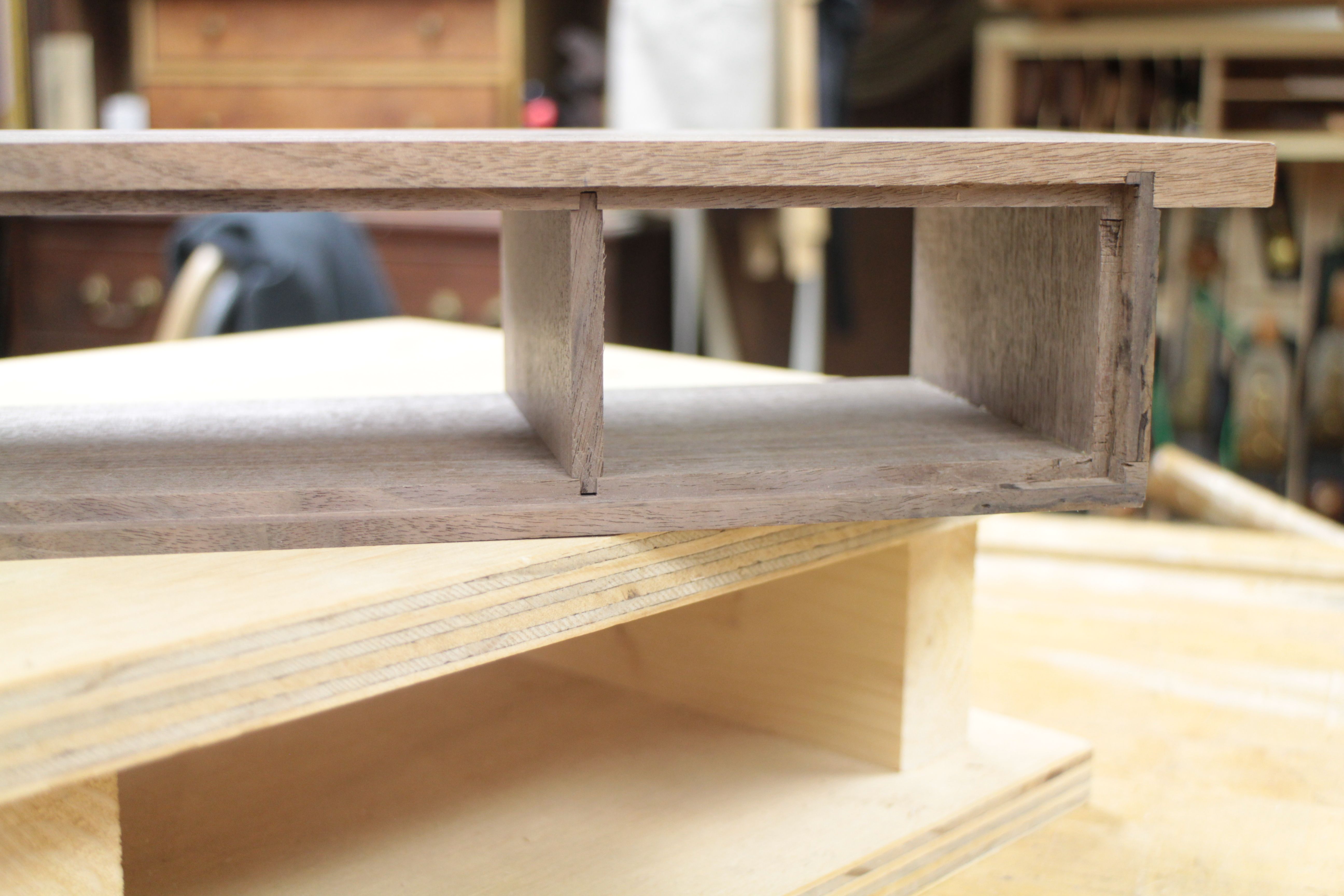

Fortunately, I know how to cut a dado with hand tools. And this turned out to be the much faster way to cut the dadoes. And it was very easy to get them perfectly aligned. With the case assembled, I used a square to mark the location of both dadoes at the same time on the back edges of the parts, and referencing the square off the top face of the shelf. After taking the case apart, I used a square and knife to mark the sides of the dadoes. I set a combo square for the dado’s length and marked both with a pencil, again referencing off the back edge. I then got to work cutting the dadoes. (There is a great article by Vic Tesolin in the next issue of Fine Woodworking that shows a technique similar to the one I used.)

Here’s what I did (see the photos above, too): First I deepened the knife-cut layout lines with a chisel. Next, I chiseled out the waste, using a chisel held bevel down and pushing it down the length of the dado. This won’t take out all of the waste. So, cut deeper down the sides with a chisel. Then go back to the bevel down chisel. Repeat until you are nearly to the final depth. Now break out your router plane and use it to take the dado to its final depth. I cut both dadoes in a less time than it would have taken me to make the shim and rout the dadoes. (If I didn’t need the shim, this technique would not be faster than the router table.)

Comments

I don't disagree with using hand tools here, but I think comparing that to a router table is a bit of a straw man. Just the other day, I cut some similar dadoes (1/4" wide, in my case) using a handheld router and a simple jig that took all of fifteen minutes to make.

Let us all congratulate saschafer for being that guy.

Yes, the old t-square and handheld router. Those work OK on larger parts, like the parts in full-size furniture. But in my experience making small cabinets like these--and I've made a lot of them--the t-square and router are not a good option. Because everything is so small, it's not easy to get the workpiece and jig clamped down tightly, and with no clamps in the way of the router. So you end up with dadoes that aren't perfectly square or aren't aligned to one another. The router table method I describe in the linked blog is a much better technique for small parts in my experience. So, I don't agree that the router table technique is a straw man.

-Matt

@BostonDB1:

Thanks; it's a tough job, but somebody's got to do it. Down with illogic!

@MKenney:

I'm just giving you the journalism instructor's critique; you haven't sufficiently made your case:

A router table is the wrong tool for this job. No argument there. (Of course, if you were going to be making a bunch of these, then it would probably make sense to come up with some kind of router table jig.) My criticism is that there's a lot of "technique space" between the router table method and the hand tool method, space that is filled with a variety of methods, involving both hand tools and machines. Because the router table method and the hand tool-only method are pretty far apart, an argument against the router table isn't a very convincing argument in favor of hand tools; it glosses over the in-between techniques that are potentially viable.

The example I gave is one of those in-between techniques. If you really want to argue for the use of hand tools, then that's the kind of technique that's the real "competition," so to speak. If you want to convince people, put up a good argument against something like that. (Incidentally, a small router--e.g., Bosch Colt--and a little forethought in jig design to accommodate clamping has, for me, alleviated the problems you mention with accuracy. In my experience, using a handheld router for small dadoes can easily work with quite small pieces, like 3" x 6", before you completely run out of clamping options.)

One other aside: You didn't actually link to your previous post (it looks like you tried, but the hyperlink isn't there).

I disagree that the router table technique I use is as far from the hand tools techniques. First, there are no jigs involved--just the router table and its fence. The technique you suggest involves jigs. Techniques involving jigs (for either hand tools or power tools) are inherently more complicated than those that do not involve jigs. I can rout stopped dadoes for a small wall cabinet on the router table much, much quicker than I could, as you suggest, give some forethought to a very specialized jig, construct it, and the rout the dadoes,and then store it in hopes that it would be suitable for another project down the road. That, I believe, puts your suggested technique further from the hand tools route than my router table technique. In other words, based on my experience in the shop. The router table technique I use is fast, accurate, and better than than the T-square technique. So, I must still disagree. I have not offered up a straw man argument.

(Stated more abstractly and pedantically: I'm contesting the truth of one of your premises. And, as I'm sure you know, if you have a false premise, then your argument is not cogent.)

But I suppose this brings up a larger point. The proximity of various woodworking techniques to one another depends upon the perspective from which you view them, and the criteria used to judge them. You and I, I think, don't agree on the criteria, and aren't looking from the same vantage point. C'est la vie.

Matt

I'm a hand tool user because I get a lot more enjoyment out of using hand tools. Period. I'm not going to win any arguments with that logic, but I'm not going to get in any arguments about it either. You kids enjoy yourselves.

This must be why the Fine Woodworking blogs don't get more traffic or posts, Knots users and by default readers of the blogs seem to be very opinionated folks. It's either the way I do it or it's obviously wrong. I imagine that line of thinking discourages people from wanting to post information and therefore the blog gets less posts and we all lose in the end.

Just my 2 cents so feel free to argue it to your hearts content.

Bob

The last two comments are by far the two most reasonable. Thank you for posting them.

--Matt

There, there, you mixed up your "they're" with a "their" in the parenthetical phrase in the caption in the second photo.

Substantively, I derive enjoyment from power tools often and often enough from hand tools. Mostly, I derive enjoyment from working in the shop and getting away from my day job. As long as you guys don't advocate using our teeth to gnaw away excess wood, this is all pretty interesting to me and I don't see the need for controversy.

In the summer I use hand tools - 11 story up in a high-rise in Chicago. In the winter, it's power tools in a heated shop.

I also love my router plane (and would have used it rather than a chisel for all the cut -- just last week I cut a series of dadoes entirely with the router plane), but there's an easy way to use the router for this if you want to. Just plan ahead, and cut the top shelf a bit long -- maybe 1/2 inch. Then cut the dadoes either moving the fence or using a shim making it a bit further in from the end than its final position will be -- it should be easy enough to estimate within 1/4 inch without any need for tweaking. Cut the dadoes, then cut the top shelf to final length.

I also use both hand and power tools, choosing sometimes based on technical aspects (efficiency, etc) and sometimes on personal preference (mood, tolerance for noise, dust...).

"Which is better" debates are inherently unresolvable without clear comparative criteria. Often they go sideways, like the quasi-formal debate here whether a router table is a straw man, which is tangential to the issue of "which is faster?"

Matt's argument was simply "power tools are not always better in objective terms (eg, faster, easier), and here's an example where I find manual work as, or more, effective than the power approaches I normally use".

Saschar's main response was "there are other powered approaches that are may be more effective than router table".

Can anyone seriously disagree with either of these positions?

That said, personally, I would probably have reached for a laminate trimmer with a base that tracks on a track guide (easier and more reliable than just guiding base against edge of t-square). I would not make a jig nor use clamps. A track with a rubber underside and a little weight on it is stable enough for the small forces of a 1/8" dado. I'm sure I could do this as fast as I could with hand tools.

Of course efficiency also depend on what tooling happens to be available. I have a laminate trimmer with a track base permanently installed, so my approach has almost zero setup costs for me. In fact, I have five or six trimmers dedicated to various functions. (note that you can buy four trimmers for the price of one Veritas router plane, so this isn't an extravagance)

Matt, I'm with you. I use what works for me. It is not about what is best, better or the only way. It is about techniques and reading about the various approaches used. Filed away and brought out to try on a project. If it works great if not there are other options.

Well I guess the statement my Dad told as a kid is true as it gets in woodworking. "Opinions are like a--holes, everybody has one".

I use what I use because it's what I like.

One question though, because I am relatively new to the craft, being such a thin dado, what do you think about a saw kerf then cleaning out the waste with the router plane?

I ask because me being new, I have yet to try either method.

Thanks for the good article.

Kevin

Log in or create an account to post a comment.

Sign up Log in