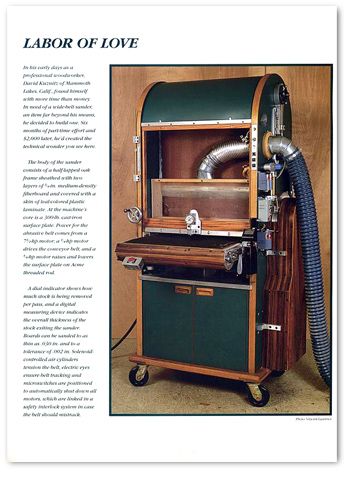

In his early days as a professional woodworker, David Kuznitz of Mammoth Lakes, Calif., found himself with more time than money. In need of a wide-belt sander, an item far beyond his means, he built one. Six months of part-time effort and $2,000 later, he'd created the technical wonder you see here.

Update – May 3, 2010: We’ve added a couple of new plans from some vintage magazines that useres might enjoy.

Not too long ago I wrote a blog about many of the woodworking machines that Fine Woodworking has shown you how to make. And by machines, I mean machines: a tablesaw, a 6 in. jointer, a bandsaw, and drum sanders (to name a few). At the time, none of the articles were available online. But that thanks to our great web produces (Gina and Ed), we’re now able to put six of them up. Take a look and enjoy. If you feel particularly adventerous and build one of them, let us know. And if you just can’t get enough, check out this blog about a shop-built bandsaw of more recent vintage.

|

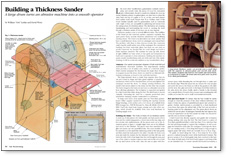

Building a Thickness Sander Back in December of 1990, William “Grit” Laskin teamed up with David Wren to author an article on a homebuilt thickness sander built from a simple motor, V-belt and drum. Laskin and Wren, guitarmakers by trade, came up with the concept after realizing that stationary thickness planers simply couldn’t plane a guitar back or top down to the necessary 1/10 in. or less. |

|

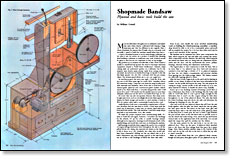

Shopmade Bandsaw If it looks like a duck and quacks like a duck . . . William Corneil’s homemade bandsaw looks, and works, just like the real thing. Perhaps the only real difference between Corneil’s bandsaw and a commercially manufactured model was the price. At $72 (in 1987 dollars of course), the price point just can’t be beat! |

|

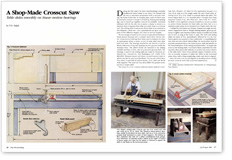

A Shop-Made Crosscut Saw Why move the blade when you can slide the bed? Sure, radial arm saws have their place in woodworking history but T. H. Ralph’s stationary crosscut saw is cheaper, and probably more sturdy than its average radial arm counterpart. Built from angle iron, a 2-HP motor, and particleboard, Ralph’s homegrown invention made its Fine Woodworking debut in 1986. |

[[[PAGE]]]

|

A Shop-Made Bowl Lathe |

|

Freewheel Lathe Drive Way back in issue 15, when the Nike swoosh was as big as bell bottoms were wide, Richard Starr demonstrated how bicycle parts could be repurposed into a foot-powered lathe that provided even power on the downstroke and upstroke. His system worked so well, in fact, that two of his lathes were in use in a New Hampshire middle school for years. |

|

Treadle Lathe Appearing in the same issue as Richard Starr’s lathe drive (seen above) was Jim Richey’s Treadle Lathe. Inspired by German-American designs as well as others from Old Sturbridge Village, Richey’s lathe was built from ashe and yellow pine and is as beautiful as it is utilitarian. |

[[[PAGE]]]

For those willing to take the plunge into homegrown shop machinery, the internet is loaded with useful links and sites containing a whole host of plans. Below are a just a few of the dozens we turned up over the course of an hour spent surfing the ‘net. Enjoy!

|

Got an Old Model T in Your Garage? Build a Bandsaw! OK, so who really has access to Model T scrap parts anymore? Still, this article from the pages of a vintage magazine has some great potential. We happened upon it on a website by the name of VintageProjects.com. |

|

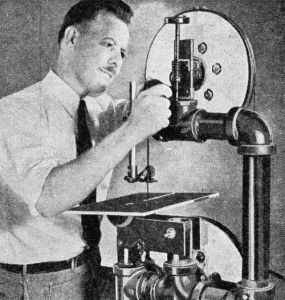

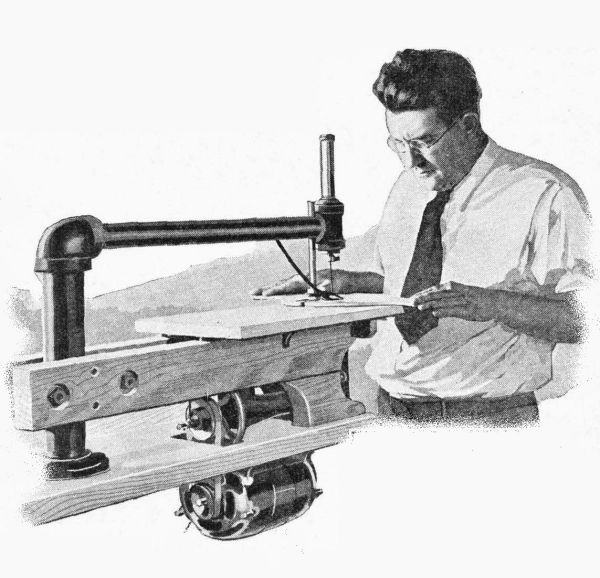

DIY Electric Scrollsaw At 1,400 strokes per minute, this powerful little scrollsaw can cut stock up to 1-1/2 inches in thickness. The vintage plans can also be found online thanks to the folks at VintageProjects.com. |

Comments

Matthew, thank you very much for posting the wonderful pdf's on the 6 machines. Please thank Gina and Ed for me also for their time and effort to make these available. Too bad there is no further information on how David Kuznitz built his amazing belt sanding machine!

Also, thanks for making Matthias Wandell's video available. I saw the earlier videos of his on the initial build but not the final results. I can only hope that I could become as capable as Matthias is.

By the way, I did notice that the Treadle Lathe article did not have a pdf available.

Oh, one other thing. Would it be possible to put the single picture (with text) of David Kuznitz Wide-Belt Sander in a pdf file as well? Thanks much, Dean

Matthew, there is another excellent article on shopmade lathes by Carlyle Lynch in FWW #57. Included is a plan for an excellent wooden bed lathe. I've used one like for 20+ years- Ron

Hello everyone: I've just fixed the link to the Treadle Lathe PDF. It should be working for you. Glad to hear the material was appreciated!

I wrote a blog on making a foot powered scroll saw. If anyone is interested follow the link http://lumberjocks.com/Tom8021/blog/10054 .

Thanks,

i have an 18" bandsaw made from a Gilliom kit that i've been using for 8 years. It works very well!

i have an 18" bandsaw made from a Gilliom kit that i've been using for 18 years. It works very well!

Does anyone have an address for the "Gilliom Kit"? This sounds like some of us could benefit from resources like that. Thanks for your help.

Fred Moretz

Log in or create an account to post a comment.

Sign up Log in