I stopped by Bob Van Dyke’s school yesterday, the Connecticut Valley School of Woodworking to scope out our shop manager Bill Peck’s progress in the workbench class. Bill’s been blogging about the class all week long.

I also got the chance to pick up on one of Bob’s little shop tips. The students say that these little tidbits are what really make class instruction so valuable.

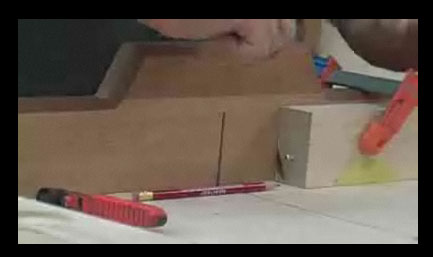

In this quick cut video, Bob shares his secret for accurate repeatable cuts–a stop block where you butt the workpiece against a round-head screw for precise measurements. The screw lets you fine tune cuts. The small surface area also prevents measurement errors from sawdust build up. John White shared a similar tip in his Shopmade Stop-Block System video though Bob swears by round-head not square screws.

What about you? Use this type of stop in your shop?

P.S. Need a tablesaw? Here’s a shameless pitch for Bob. He asked me to get the word out about a tablesaw raffle at his school. The drawing will be October 31, 2010 or as soon as all tickets are sold.

Comments

What a great tip.

I have always used a block of wood with the bottom corner cut and I would agree that a lot of time is spent positioning that block before making all your final cuts.

This idea is great allowing that micro adjust ability.

One thing that comes to mind would be to use a hardwood block such as eastern maple as the stop block so that over time the screw will not loosen in the pre-drilled hole.

Thanks again

Log in or create an account to post a comment.

Sign up Log in