All About Surface Preparation

No matter what type of finish you choose to put on a project, the end result will depend upon the degree to which the surface was properly prepared.

The Basics:

• Planing: Hand planes offer a nice surface, while machines are rough

• Scraping: A well-tuned scraper can create a glassy surface

• Sanding: Success grits lead to a polished finish

Individual woodworkers have strong opinions as to which method produces the best results, and heated arguments emerge from the debates about using one instead of another. In truth, many woodworkers often employ more than one method. Horizontal surfaces, such as tabletops, need the most care because they reflect the most light at an angle which is more visible.

Planing

Electrically powered machines such as planers and jointers are usually not capable of supplying a finish-ready surface to a project. The knives chop the wood surface in a series of cuts that can sometimes leave a slightly rippled surface that is too rough to result in a smooth finish. Hand planes are another matter: they shave the wood in long, clean slices and leave an incredibly smooth surface. Compare the ribbons coming off a well-tuned hand plane to the sawdust flying out of a power planer, and it’s easy to see the difference.

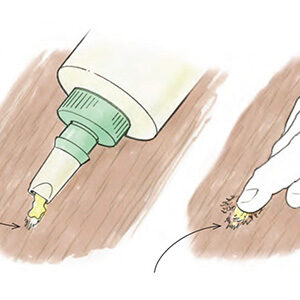

Scraping

Scrapers cut very thin shavings off the tops of the wood fibers on a surface. They also partially burnish the surface in the process and leave it shining and ready for a finish. Dull scrapers do not shave off the wood fibers, but only burnish the surface and accomplish little improvement to it in the process. A well-tuned tool is critical for getting decent results.

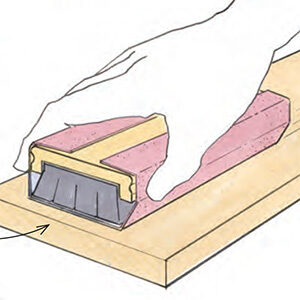

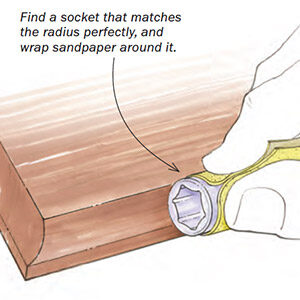

Sanding

Sandpaper abrades, or scratches, the surface of the wood, removing layers of wood fibers in the process. The great advantage to using sandpaper, unlike hand planes and scrapers, is that there is no tool that requires tuning. You can use a fresh sheet of abrasive paper and toss it when it gets too dull to do the job. Also, by employing successively smaller grits, you can control the scratch pattern and make the surface as smooth as you want it to be. For preparing a wood surface for finishing, start with 80- to 100-grit paper, and carry it through to 180- or 220-grit, which is as far as you need to take it.

Fine Woodworking Recommended Products

Odie's Oil

Bumblechutes Bee’Nooba Wax

Waterlox Original

Log in or create an account to post a comment.

Sign up Log in