In the article Torture Test for Outdoor Finishes (FWW, issue 205), one of the best finishes was the combination of a penetrating epoxy sealer under Epifanes marine varnish. Originally demonstrated by Sean Clarke in FWW issue 179, on a recent trip to see Sean in Columbus, Ohio, he took me to see a church door that he had used this finish on three years earlier. Despite having snow shovelled against it for much of the winter, the finish looked as if it had been applied last week.

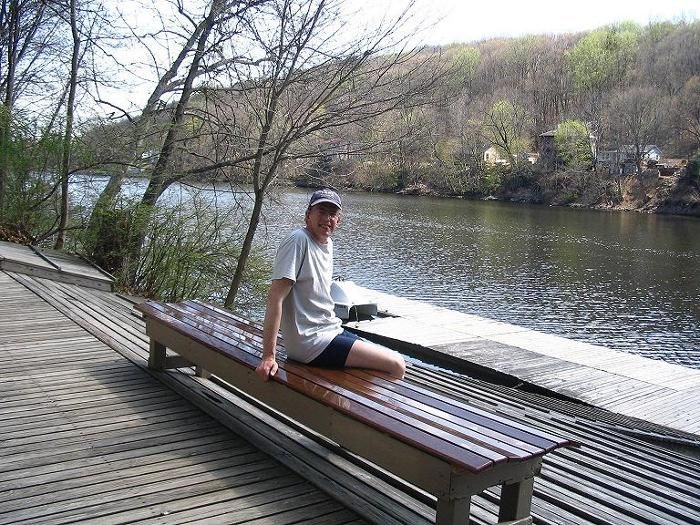

I decided to use this finishing method on a bench at the New Haven Rowing Club, of which I’m a member.

| More on outdoor finishes: • Torture Test for Outdoor Finishes • A Durable Exterior Finish • Wood Against Weather |

The bench top had consisted of two, 11 in. wide, 11 ft long boards of Honduras mahogany. Because of their width, the boards had cupped badly and held standing water after it rained. The only solution was to rip each board into four slats, remove the old finish and start again. After applying two coats of the epoxy sealer, I sanded the surface, then applied an oil-based grain filler. Not only was this to fill the open pores but also to fill several areas of checking where water had got under the old finish. After removing the surplus filler, I applied one more coat of epoxy and then started using the Epifanes varnish. In all I brushed on 7 coats on the top, sanding with P320 grit between coats, except for the last penultimate coat that was wet sanded with 600-grit paper. For the final coat I thinned the varnish by about 50% and wiped on a coat with a cotton rag. In this way I was assured of a smooth surface that dried before dust could stick to it. The underside received five coats that were not sanded between coats.

I created a new profile for the support cross pieces that not only is more comfortable than a simple flat bench, but it also angles each slat to help it shed water. The bench faces southwest so the UV protection in the varnish will be given a good test, but hopefully I won’t need to re-varnish it for several years.

| More outdoor furniture projects: • A Classic Adirondack Chair • An Outdoor Table in Ipé • The Lutyens Garden Bench • A Japanese Garden Bench |

Comments

Great project Mark. Your club is lucky to have a woodworker around! -Gina

Has anyone heard of this: Exterior Alkyd paint!. Deep tint base thinned 50/50 for the first few coats and then 40/60. Its grey in the can but dries crystal clear. Has the UV protection and toughness of exterior paint.

When I first heard of this, I did not believe it. The guy who told me about it tested it on some doors he left out in the Texas sun for years. I used this method on the front door I made last summer. It does not have a storm and got beat by the tough Michigan winter we had this year and looks great. It works!

John,

It makes sense that paint without the binder would work but I've never heard anyone doing it. Any particular brand of exterior deep base tint? Were you brushing it or spraying and are the last coats 40% paint or 40% mineral spirits? I'll have to try it. Thanks!

Interesting idea. I would be curious to find out what the product was as well. I was also curious Mark as to why the recent article in the magazine doesn't include products like D-Dur post cat urethane or Euro-X from ML Campbell? These are 'professional' options for exterior clear film finishes and it would have been much more interesting for many of us if these or competitive alternatives were tested along with the typical spar varnish and such?

FWIW, a 7 coat schedule may work for a smaller project like this bench but my current task involves an entire (large) exterior porch and railing system where it would not be practial. D-DUR and the like are spray applied and much more friendly to time in that regard.

The subject or what works and what doesn't for exterior finishes has been around the horn many times over at Woodweb with no real concensus other than nothing lasts in the elements. To me it seems like an opportunity to shed some light on what seems a very gray area and the article only scratches the surface by missing some readily available coatings, possibly including the pigment free paint base idea! An update to this would be a great idea for next year!

I was surprised that the recent FWW article didn't test any Sikkens product.

I have used Sikkens Cetol 1 on my cedar outdoor furniture for more than 10 years. The finish on my cedar table (under cover) still looks like an indoor furniture grade finish despite heavy use for 7 years.

The same product on cedar adirondak chairs (fully exposed to sun and rain and snow - NY climate) holds up for at least 3 years before needing an additional top coat. When fully exposed, the finish wears off but doesn't crack or split like a poly. It breathes and moves with most wood movement. So every few years I take a little steel wool to it to remove the grime and put on an additional coat. They still look great and the only place the finish has failed was where my labrador puppy (now 8 yrs old) made some teeth marks in the arms of the chair. In those spots the wood darkened because the finish failed.

Living in Miami, I do tons of work on ocean-front condos & homes. One condo community I work in has terrace window-walls made out of teak with french doors & lites. I've been using the Epifane with incredible results. I prep the teak with the usual scraping, sanding & solvent wiping down; then apply a first coat thinned 50-60% with Epifane's thinner, sand with a fine or extra-fine sanding sponge; second & third coats thinned about 40%; top coat thinned 25-30%. I can usually stop at 3 coats for indirect sun but will use 4 or 5 coats in direct sun - definitely 4-5 facing the ocean. This is the best & longest lasting finish I've used - - - must be why I get so many referrals!!!!

I have to agree with Swirt. I have used this product extensivly on boats and in my home. It is amazing. It is not cheap but neither are the other products.

Hi folks,

I have for years built epoxy cedar strip canoes. Once when I was redoing my bathroom I used left over cedar with an epoxy and 2 coats of marine varnish for a shower surround. That was 20 years ago. I have recently visited the people who bought the place and the shower surround looks like it did originally. There are two problems with using this for a shower surround. The tops and bottoms of the boards must be well sealed with silicone to keep the back of the boards from becoming water logged. As well, soap and hard water scum show up easily. A good cleaner that removes the scum with out stripping the varnish is needed.

Be Prepared! I used Epifanes on a teak swim platform that was mounted six inches above the water on a docked boat six months of the year. It was always wet from wave action. It was wonderful to apply and was certainly an attractive and durable finish. It lasted a full three years in this repeatedly wet environment which is the best I ever achieved with a wood swim platform. But when it came time to refinish I couldn't find a stripper that would touch it and I had several of the old heavy duty but now illegal strippers in my shop. I finally gave up and took it to a local furniture stripper, got a $90 firm bid to strip it, and left it in their hands. After a few weeks, several phone calls, and comments of "we're still working on it" I was told to pick it. When I got to the strip-shop the scowling owner took my $90 and told me to never bring that swim platform back with that finish on it. They also had been unable to find a suitable stripper and had manually scraped all the old finish off - certainly not an easy task because of the slatted design of the platform. I'll have to admit they did a beautiful job.

Beautiful project. Really like the profile you put on it, looks comfortable. I'd be pleased to know your support profile measurements - length, height of ends, high points and center.

I have an ipe rail cap on my deck in Santa Cruz, CA. 12 years ago I applied a marine spar varnish but 3 years later had to sand it all off. I applied the epoxy/epifanes solution described and have been very happy ever since. It gets full UV exposure all day. The key step needed to keep it looking great is an annual light sand and re-coat. If you see a void appear in the finish during the year sand and re-coat sooner. If you let it go you have to take it all off. No finish is perfect outside but this one seems to work very well. I'm leaving my outside ipe chairs without a finish as I don't want to sand and re-coat everything every year (I'd rather build some new items!), but for a rail cap the visual impact of a nice finish is well worth the 3 hours annualy to keep it up!

Thanks for all your suggestions and comments. Our aim was to pick a representative from each type of exterior finish rather than several marine varnishes or several spar varnishes etc. If we do a follow up test we may test just the most durable finishes such as professional spray-applied ones, other marine varnishes and maybe the non-pigmented paint. We'll probably have to leave the boards up on the roof for several years before publishing the results!

Doneby, I'm quite glad to to read about the trouble you had stripping Epifanes. I think the secret is that as soon as the surface dulls, or the finish is damaged, scuff sand it and apply another couple of coats.

Farmer2, I think the width of the bench to is about 20 in. and I made the top a shallow W shape as people sit on it from both sides. From peak to trough it is only about 1/2 in. If I was making it for a one-sided top I'd probably go a little deeper. The end slats overhang the cross supports by about 3/4 in. Everything is screwed from underneath.

Love the bench Mark, great job. I would like to respond to Stevecater comments on the ML Campbell products verses the varnish. It is true that the Krystal is a good product; however it is tough to maintain. Also the epoxy/varnish system can be sprayed, just like the krystal. The varnish system is easy to repair, and recoat. The epoxy in this system helps to fight dry rot, and stops active dry rot in its tracks. Also when it does come time for that top up coat, you can purchase the varnish by the quart. The post catalyzed urethanes only tend to come in gallon kits, and are particular about their reducers. I have used the solvent based urethanes, on many projects, and love them, but I think the epoxy/varnish system is best, when applied correctly. Plus if you apply extra coats of varnish at the start of the project, you can possibly add several more years to the life of the finish. One the other hand, if the thickness build on post catalysed products exceeds 6 mils, it becomes unstable, and could crack once it reaches full cure.

I am getting ready to finish an exterior Spanish Cedar door that faces west. I am located near New Orleans, La which means I have to contend with sun, heat, humidity and plenty of rain. I called Epifanes to locate a distributor near me. They told me of a marine supplier that carried the Epifanes high gloss varnish, but they also told me they package the same product in the marine suppliers own brand. I was able to purchase it for $29.95 vice $45.00. If anyone wants to use the Epifanes brand,call them and see if there is a supplier in your area and if it is packaged in the store brand.

Hay WOFO,

I live in NO also. Just finished a cedar outside dropleaf table. How did your finish work for you now that we've hit 90 degrees in May? I need to finish my table but can't decide on best finish to use for this sun, heat and humidity.

K

Great work, Mark. Thank you for your post. You mention "after applying two coats of the epoxy sealer, I sanded the surface, then applied an oil-based grain filler" and also mention that you thinned the final coat to 50% applied it with a cotton rag.

I would appreciate knowing what epoxy sealer and grain filler brands you used or recommend, as well as, commenting on the potential for a lint problem with your use of cotton rag for the finishing coat.

I am also wondering if you and or Sean have tried or could comment on the use of Epifanes' WoodFinish Gloss in lieu of their High Gloss varnish (it is a more porous alternative very similarly manufactured with Tung Oil and Phenolic Resin plus bit of Pine Resin that does not require sanding for adhesion within 72 hours of application in between coats), known to reduce labor while producing an identical though less UV protected outcome.

Finally, I could not locate Sean Clarke's piece (#179) and wonder if you could kindly forward a copy to me at max.danes@adupsys.com

I'm looking to finish my front door, Brazilian Mahogany, and happened upon this post and several others that mentioned the epoxy/varnish method. What I can't seem to get over is, if I were to apply 6 coats of marine varnish, like say, Epifanes, why would I need an initial epoxy coat? Does the epoxy add UV protection over what the marine varnish gives? Seems like an unnecessary step because the marine varnish already protects from moisture, and multiple coats of it should attenuate UV to almost nothing by itself. Why the epoxy?

You've done some great work, Mark. Cheers !

If I had the chance, I would spend hours on this bench reading a book...

Log in or create an account to post a comment.

Sign up Log in