How do you cut your tenons? Vote in our poll.

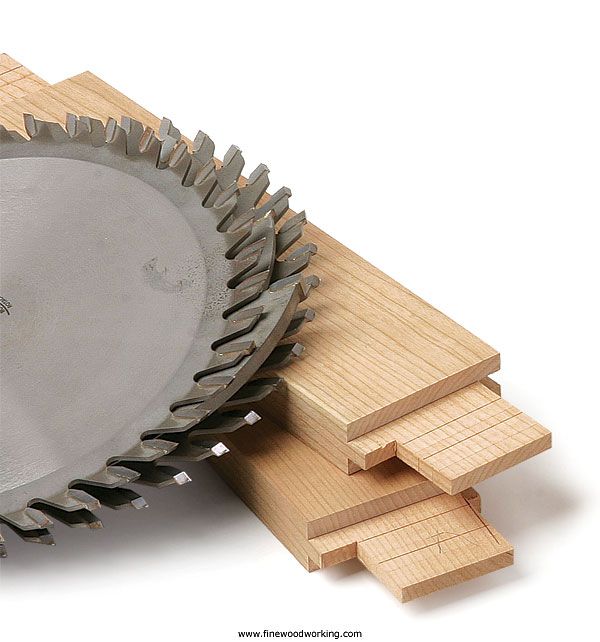

There are many ways to cut a tenon: hand tools, bandsaws, a variety of tablesaw methods, router techniques, and more. What’s your method of choice? Vote in our poll.

We’re doing a round-up of the most popular techniques in anticipation of our Tenon Shootout Jan. 21 at 1:30 p.m. ET. During this live video event, two FW staffers will face off to find out which technique is the “best.”

Comments

In your poll you fail to provide for the use of loose tenons as for example the Domino system!

I make mortise and tenon joints ranging from simple hand tools up to the Leigh Frame Mortise and Tenon Jig. The first time I used the FMT I did a test fit of a joint. When I pulled the tenon out and the heard a loud "pop" from the vacuum I knew I had experienced something special. But, there are times that I use hand tools just for the pleasure of it. For me woodworking is a hobby and I don't do it for a living.

the Woodrat router system cuts the quickest, cleanest tennons. Once you have a spacer block for the width of the tennon you require (ie for each mortice you use) just cut stock to length, set router depth to the length of the tennon (max 50mm)clamp in stock and secounds later you have a neat sharp square edged tennon. It can lso cope with angles for chairs etc with simple logical jigs and you see what your cutting!

I use a radial arm saw, a band saw and chisel combination, a Japanese ryobi saw also is brought out. Cut many tenons for my railings in my timberframe home.

OK, I built one of the tablesaw jigs and can cut a pretty good tenon. But what good is tenon without a mortise? When is the mortise "shoot out?"

I have to say that I found the tenon shoot out article in the magazine,with its focus on speed, a little bit pointless. Surely the best tenon cutting technique is the most appropriate for the job and you. This will depend on a number of factors, sometimes hand cut and sometimes machine cut, including:-

- Number of tenons to cut;

- Size of tenons;

- The type of tenon;

- Strength of joint required;

- Material to be used;

- The tools and equipment you have access too;

- The time you have to complete the job;

- and last, but by no means least,the amount of satisfaction you require from have cut a well fitting joint by hand.

As a child I was read the story of the hare and the tortoise and learnt that being the fastest does not

necessarily mean you're an automatic winner!!!

Not enough combinations to choose from. I use the table saw to cut the shoulders; the bandsaw for the cheeks; and then clean it up and fit it with a shoulder plane. Its quick, extremely accurate, and I don't have to mess around with putting a dado blade on or setting up a jig or fixture.

woodrat wins the prize....quick clean and accurate

Log in or create an account to post a comment.

Sign up Log in