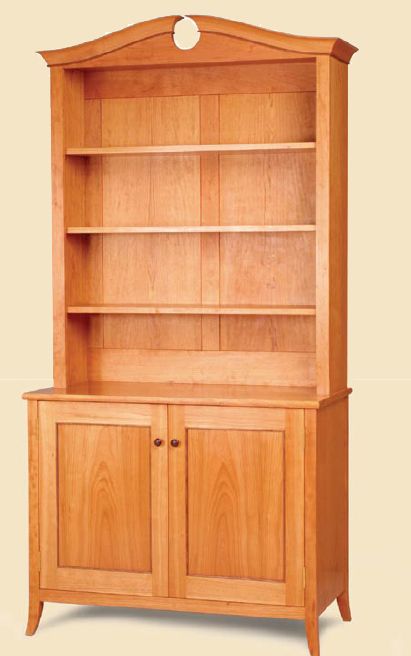

What do you think about plywood and fine furniture? Mark Edmundson created this freestanding piece using special techniques to overcome the inherent drawbacks of using plywood.

In these tough economic times, it’s tempting to skimp on solid wood and opt for plywood to save a few pennies. What do you think? Are you a solid-wood purist? If not, how do you use plywood in your furniture?

Take our poll, check out our list of tips for working with plywood, and then weigh in with a comment below. Do you have any other tips for working with this flat and stable material?

Veneered plywood works well in built-ins, panels, or even large tabletops since it doesn’t fall prey to wood movement in the way that solid panels do. And, plywood covered with nice hardwood veneer and some solid-wood edging gives it the feel of a solid-wood piece.

For instance, Mark Edmundson created this freestanding cabinet to take advantage of the benefits of plywood. Namely, that many of the “best logs are scooped up by veneer mills” and he wanted to use them for his work.

Mario Rodriguez, in 6 Ways to Edge Plywood, even ranks plywood innovations right up there next to the invention of the tablesaw.

If and when you incorporate this handy material into your work, below are some helpful tips.

- Dadoes and biscuits are good joints for plywood

- Hide unattractive edges with edge banding or face frames

- Iron-on veneer tape works for protected surfaces

- Apply solid-wood edge banding in high-wear areas

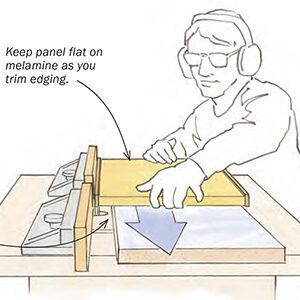

- Be careful trimming edging to avoid damaging the veneer

- Avoid the standard 3/4-in. plywood look by creating thicker, custom panels. Just glue two 1/4-in. plywood to a core of MDF.

- Use caution breaking down large sheets on the tablesaw. Get a helper if you can for your first cuts.

- Or cut roughly to size with a circular saw and then make finish cuts on the tablesaw

- If pieces are too large for the tablesaw, make finishing cuts with a router with an edge guide

- Avoid tearout by scoring the cut or covering it with tape

- A zero-clearance throat plate also helps to reduce tearout

- Use a triple-chip blade with a high tooth count for ripping and crosscutting

- Delivery pays: Let the supplier deliver hardwood-veneer plywood to reduce the risk of damage in transit

Comments

That which makes furniture "fine" has almost nothing to do with what materials are used, and everything to do with how they are used.

I agree with saschafer. I am working on a painted piece right now that uses plywood, MDF and poplar. I don't use plywood for stained work simply because I don't have a convenient source for good quality plywood.

I don't have anything against plywood, but I don't think high quality plywood saves any money. In fact I think it often costs more that the equivalent hardwood. I use ply for carcasses and drawer bottoms and case backs. If I needed large sections of clear cherry or walnut, I would probably consider plywood. It does save time though.

Good veneer work requires two veneers, a top finest grade piece and bottom lesser veneer for stability, with an inexpensive stable core.

Isn't that plywood, with a couple less middle veneers?

Do you really think if good quality plywood was available two, three, four centuries ago we wouldn't be having this conversation?

I find that I mostly use plywood for shop-grade woodwork, but I have used it in "good" furniture too. My big complaints with plywood is having to deal with the large unwieldy sheets (minor, as there are many ways around it), the splintering often due to the thinness of the veneer. I've been buying pine plywood recently for my shop and am starting to really like it because of the nice thick veneers.

My favorite plywood is "form ply" or "balcony plywood". The paper face and almost solid core seems to last along time when exposed to the elements. I have made raised panels out of it for shutters on windows when the width required exceeds 16 inches. I find glue ups of solid wood weather poorly and expansion/contraction problems occur above this width. With proper backpriming and good paint I have seen no problems in the 20 years I have been using it. Good luck George.

While I like the benefits of cabinet grade hardwood plywood what really bothers me and makes me very reluctant to use it is the paper thinness of the finish ply. It offers almost no durability, is very easy to sand through, and splinters quite easily. It might work well for wall cupboards but just isn't durable enough for tops or floor cabinet sides.

On the other hand regular plywood with a much thicker outer ply can work well for shop cabinets or when painted.

I've made a number of pieces for our church using oak plywood and solid oak for the edges, including a lectern that is in use every Sunday in our sanctuary. Everything I've made has met with enthusiastic approval. But if I could do it again I would make the lectern from solid oak. Maybe it's just because I know in my heart that I could have done better. It looks "very nice", but it's not "excellent". D. Urban

Vacuum bag!! I use plywood extensively now for any parts that does not require a finished edge or an edge that is easy to deal with. I find that by resawing good quality solid wood i have access to goregeous finish and with the plywood i obtain satability. Best of both worlds.

I have been using cabinet grade plywood for years on table tops, end tables and entertainment centers. Experience using plywood helps for sure. Once you learn how to use it, I believe it looks just as good and wears longer than solid. With the proper finish and sanding techniques you can really make your pieces stand out against and i do save money

I am currently renovating a bedroom/soon-to-be- baby's room. I've used maple and birch plywood to build a small bookshelf built into the room's knee wall and for the built-in wardrobe and cabinet.

One innovative thing I've done is I've cut a 4x8 sheet of maple plywood into 8' long 4" wide strips that I'm using for baseboards. To cover the exposed plywood edge I've used 1" x 3/4" strips of cherry (to match the cherry hardwood floors.) It saved me a bundle over using solid maple for all the baseboards.

I have been making small decorative boxes for a few years, and for most, I use plywood for the bottoms. I set it into a dodo, and I like that it is more stable and stronger than solid wood of the same thickness. In applications where the edge is in play, I would not use plywood. I think plywood is a quality product and has its applications.

I used plywood for cabinet doors and drawers in the mid 70s and the quality was acceptable for the mid-range contemporary houses we were working on. Recently I went to a reputable dealer and bought a load of birch 3/4", 1/2" and 1/4". I found it to be inconsistent in thickness and subject to warping rapidly after being cut. Some sheets were actually 11/16" along the factory edge.

The problem, as I understand it, is lack of consistent standards in a worldwide lumber market. Also the dealer claimed that he had no information as to what material was used in the core layers.

I found some better grade sheets at Home Depot, manufactured under the name "PureBond" that contained fewer ply layers, but behaved with more stability and were more consistent in thickness. I was told by a Home Depot employee, who I asked to contact a sales rep, that the individual plies are mechanically dried before laminating.

PureBond is fine for mid-range projects, but I would advise the customer that I planned to use it.

If I were making "fine" cabinetry I would use hardwood.

The poll question is a fine example of what's wrong with a truly great magazine. It is so clearly evident in the choices that someone feels that plywood carries the plague and other dread disease along with giving away the work product of a hack. (No... not Garrett).

"saschafer" hits the nail on the head when proclaiming that the "fine" in "fine woodworking" has little to do with the work. And "michael2160" is spot on with his rhetorical question... if Goddard and Townshend had plywood available to them in 1750 Newport there is no question that they would have used it for cabinet backs and drawer bottoms and even case sides for "upstairs" pieces.

Taking an editorial position that is "anti" plywood in this day and age is absurd and, frankly, irresponsible. When a customer insists on all solid wood and no plywood I turn the job down. As has already been pointed out... anything with veneer on it is "plywood" and anyone who is acting responsibly should be using the stuff when it saves material and extends the life of the finished piece.

There is little to disagree with in the previous postings. I too tend to use plywood for utility pieces only and then typically for carcasses and drawer bottoms.

On the other hand, I don't much like the lack of versatility in the types of hardwood plywood choices available. I don't use red oak much these days and I have found cherry and maple, etc plywood too expensive.

There are some pretty decent solid wood choices available out there that are also fairly inexpensive and pretty good at resisting normal abuse. I recommend considering southern pine, elm, ash, or hickory as alternatives to plywood. With some diligence, even poplar can work pretty well for some projects. Some resawing and simple lap joints work well for cabinet backs and drawer sides and bottoms.

For me, the use of plywood boils down to two things. First, am I creating an heirloom? Not everything fits in to that category. Second, wood movement. I just designed and executed a piece that had a very tricky relationship of wood movement. So, I used plywood for the base. I used box joints and dados to create strength points. Then I wrapped it in 1/8 inch black walnut.

One other note. Some previously mentioned that fine wood plywood is very expensive and doesn't save much. That 100% true. I will say, that it save a lot of time.

Enjoy!

Marc

I've found that oak plywood has the color of oak, but the grain pattern looks nothing like a piece of oak. It has the typical wild plywood grain pattern. Maybe there are better grades of plywood that this isn't as noticeable

I have to agree with srtu3456. Solid Cherry selects in my area costs <$4/bf while 3/4 flat sawn cherry ply runs $150/sheet and at 32ft² per sheet that's $4.70/bf. As such selection one in the vote box seems contrary to reality. I have no issue using ply if the one can not (without advanced knowledge) discern if it's solid or ply. That speaks to the quality of the ply and dealing with the edges in a way that they become invisible. Simply edge banding a slab of ply and calling it a door screams IKEA not FWW. michael2160 echos my sentiments. I say the same thing about hardware, finishing etc. If cabinet makers of centuries past had advances available to them such as concealed full extension slides with motion stops, catalyzed lacquer finishes, sandpaper etc etc they most certainly would have used them, ditto for plywoods.

For just a couple extra bucks one can buy plywood with plainsawn veneer. It more closely resembles solid wood, eliminating the cheap look often associated with plywood. For work that's to be painted, birch or maple plywood is flatter, smoother, cheaper and more stable than solid wood.

I don't use plywood because I don't like working with it. With the exception of a mini-lathe and drill press my shop is entirely hand powered and plywood just doesn't work terribly well with hand tools. The glue is really hard on saw blades, plane irons and chisels and I don't think most traditional joinery would work well with plywood. I don't even want to think about what a disaster it would be to try to smooth plane the face of a plywood panel...

For those reasons I doubt an 18th century cabinet shop would bother with ply even if it were available.

I do admit I've been tempted on a couple of projects to just buy a sheet or two of hardwood ply to use for a case back to save time and/or money on a project. At my local hardwood dealer 1/2" furniture grade walnut and cherry ply is pretty much the same price by the sqft as 4/4 solid wood from the racks. If I was buying my hardwood at local retail prices that would be fine for the time savings. However I tend to just accumulate wood independent of any specific project and have scored some great deals on ebay, craigslist and the Woodnet forums over the years for far below local retail prices. It's just cheaper to dig around in my stash than go out and get ply.

Plus when I need to haul lumber myself I can fit about 30 bdft of 8' hardwood boards in my VW Golf (with the hatch closed!) but can't accommodate as single full sized sheet of ply.

Cheers,

Josh

I use furniture grade plywood quite extensively. Always for pieces that are unseen, usually for panels and the like, with solid wood reserved for edges and frames where joinery is either necessary or a feature of the design. I may or may not use it for tops, depending on the design and appication. I accept the fact that on the basis of board foot pricing good quality plywood, carefully chosen, is no cheaper than solid wood, but whether I am doing a piece for the love of it or for a price, I value my time, and not at some miserable minimum wage rate! There is no way solid wood can compete with plywood when supply price and labour time are taken into consideration for the uses I put it to.

While I agree that were I to be making an heirloom piece or a commissioned piece where price and time was of little concern, then for sure I'd go with solid wood all the way, but in my neck of the woods, if I confined my building to producing for whom cost was not an issue, I wouldn't be spending much time in my shop. The reality is that the vast majority of people who want a custom piece of furniture or cabinetry still have a necessary eye pinned on price, and so plywood is usually a part of the solution to produce a beautiful piece at a reasonable price.

Many have talked about breaking plywood down with a circular saw before using the table saw, and I do this extensively. I have a self made cutting guide, designed like a flat truss to avoid warpage or deflection, which I clamp to the plywood sheet to guide my saw with a fine toothed, thin kerf blade. If the particular piece is to be lodged in a dado, that is my final cut, whether ripped or cross-cut (with the use of tape of course). It it needs refinement, I use the table saw with my glue line blade and that is the final cut before actually gluing.

So...that's my two cents worth.

It is interesting to see the poll results that 40% use it to save a dime????!!!!!!! Whoa! There goes "woodworking". Hopefully those that voted that way really mean somewhere in between the "occasional" use and this one.

That answer to me is the "DIY" network way. Even in this economy using plywood to save a dime on the front can mean a rapid cheapening of the value of woodworking. Saving a dime up front can quickly mean loosing a dollar later - quality and lasting construction both in the construction and finish; resale value (if that is what you are doing), etc.

I go back to the DIY network. I've seen them so many times literally "throw" together some ridiculously looking, and constructed, shelf unit, entertainment center, etc. that won't last past the cameras being turned off. It is such a shame what people are willing to accept these days; and, NO it does NOT cost that much more to do it right! People just don't seem to know better. We are dumbing them down in quality.

I am a big advocate of the PROPER use of ALL materials in woodworking and anything for that matter. Just please don't start us on the trend of saving a dime only to loose a dollar.

I use it for the backs of bookshelves, it's stable and does the job.

Whilst the price per BF is frequently higher than hardwood lumber, it saves time in this application versus cutting hardwood to 3/8 and using half-laps as was customary prior to plywood.

Were I to make a reproduction piece, I'd have to do it the old way, but that is the reason reproduction work commands the prices they do.

I've used plywood for things like bathroom shelves, where there is a high humidity factor and find that cutting slightly over-size then coating the sanded edges with multiple coats of Titebond III, sanding between coats, gives me a uniform surface that resists separation, sands well and has a good appearance even without banding, when painted. Needless to say, that's not "fine woodworking" but it's pragmatic as heck.

Veering slightly off topic, coating the cut ends of pieces used outdoors with Titebond III improves resistance to water damage immensely. If one is painting the pieces, then it's undetectable, if staining, one has to tape the ends carefully prior to coating to avoid bleed-over.

I think there's a big difference between casework (such as kitchen cabinets or the carcases of built-ins) and "fine furniture."

I make both. Like everyone else, I use plywood extensively for casework. Good material, and stable.

BUT what I enjoy most is designing and constructing what I consider "fine furniture." And I just refuse to be constricted to the right angles and flat surfaces designing around plywood requires.

Designing around plywood means no gentle swoops in the surface, extra seams, no fluid edge treatments. Sorry, it just doesn't work for me in "fine furniture," except maybe for backs or drawer bottoms.

New to woodworking, I must ask what may seem to be a dumb question. If you spend $100 +/- for a sheet of hardwood plywood then do you put a veneer top on it? Or, just paint or stain it? When I use real wood I seem to always stain, not paint. When using plywood or MDF I always paint.

I know on the edges it needs banding of some sort but I do wonder about applying a veneer over a hardwood plywood.

Thanks,

Jerry

"Fine furniture" doesn't just refer to "what you like to build". Some of the comments above are the usual bigotry I read in FW from time to time.

For Arts and Craft or Mission styles, plywood is a great alternative for hardwoods in panels and large shelves. Use of solid wood to build frames that you can set plywood panels in can be more stable and look great. But wait, that probably isn't "fine furniture" is it.

Plywood words well for contemporary pieces as well.. Ah, again I err. That's not "fine furniture" either is it. ;-)

Some of you need to broaden your scope a bit.

Using plywood doesn't necesarily make things cheaper. The desk I'm sitting at as I write this is made largely of 3/4" oak veneer plywood which runs about $40.00 a sheet. There was also solid oak involved as well. While I made the desk much cheaper than I could buy it, it was hardly made on the cheap. As a bonus, it is also custom fit and custom designed to suit not only my needs but also my work area. There is nothing shoddy about it. The oak veneer finished just as nicely as the solid oak elements.

I don't limit myself in materials. If oak plywood seems like the best choice I use it. If it's not right for the project I don't. It's as simple as that. And oh yeah, I make a lot of "fine" furniture, some of which contains as much as 80% oak plywood. I agree with Saschafer. That which makes furniture "fine" has more to do with workmanship than material.

I use a lot of plywood for drawer bottoms and cabinet backs. The stability of plywood works for me in these applications, and I think a decent grade of plywood actually is better for drawer bottoms than solid wood.

I also use a lot of sheet goods for shop cabinetry and projects. Much of the plywood I use is Baltic Birch in 5x5 sheets. I love the stuff - solid, without voids, smooth surface and the edges will sand up nicely for shop cabinet drawers.

I will also use plywood for large panels in a panel door. I can get a decent quality 1/4" plywood sheet far cheaper than I can get solid wood. It doesn't weigh as much as solid wood and I can glue it to the rails and stiles to make the door stronger. This isn't a fine woodworking application, but a good practical one.

Here in the San Diego area, I can get good quality plywood sheets for a reasonable price. I do avoid rotary cut sheets if possible because they look weird. Solid cherry, one of my favorite woods, is really expensive. I cringe with envy every time one of you writes about getting cherry for $4/bdf. Around here, 4/4 cherry select and better is $7 to $9 per bdf for plain boards and you are lucky to get good boards with decent grain and without a lot of sapwood. If you aren't at the lumberyard when they break open the lift of wood, you aren't going to get good cherry, walnut or many of the other woods for that matter. I have been thinking about trying some of the mail order providers back east to get better quality of wood.

When it is time to make something really fine, I will go with solid wood, although I have to admit that the back or bottom may end up being plywood.

Hi all

Some good ideas here. I have used plywood in the past for doors and other large panels. I only use solid glue-ups now due the fact that high quality ply is not available in my area. I live in a small town. The big box stuff for 50 a sheet doesnt due justice to a project.

I have a Supermax drum sander and for me doing a glue up and flat sanding the panel is no problem.

Just some thoughts. Paul

Plywood has its place as does most things in life. I use it for carcasses, drawer bottoms, and backs. But the whole concept of "fine furniture" has to do with the eye of the beholder, which is based on the skill of the craftsman who built it. I have only started woodworking in the last two years and the quality of my work is not up to the standards of what I consider "fine furniture" and it has very little to do with the materials I use. Since most craftsman start out with the highest quality materials they can get I don't see how materials have a lot to do with it

It is not always a matter of saving money. In some cases, it is saving precious wood. I am presently building an end table with a Honduran Mahogany top. Since this wood is becoming scarce, I am putting my 1/16 thick shop made Mahogany veneer on a plywood substrate, with solid wood edge banding. The finished result will be very nice. I recently built a hall table with curly Koa veneers on the top and drawer fronts. With woods that are in short supply, using veneers on plywood or MDF substrate is the responsible way to utilize these resources.

Interesting that no one I saw said they didn't use it.

Even if I cut the dovetails by hand, I'll use sawn veneer plywood for the bottom. You can then glue it in place. This prevents racking of the drawer, which is the usual failure mode. This is one time when solid wood is far inferior structurally because you can't glue it all around. And the sawn veneer has a very good look.

I work out of a very small and cluttered garage and do most of my cutting and sanding in the driveway. I have made two tall book cases and a tv bench out of nothing more than red oak 4 x 8 sheets and 1/4" oak for the back panels and these projects have turned out beautifully. I purchase the sheets at either lowes or home depot and have them rip the panels to my desired width so that I can get the stuff home in my 4 door sedan with folding rear seats (who needs a truck!) I have a handy new clamping device andI do all of my cuts (including inset door panels) with a circular saw using a good freud blade. Patience and attention to detail is pramount in using this saw as I can cut perfectly square inset doors to the 16th or even 32d using the saw!! And then I use the glue-backed iron on veneer strips edge banding which can be sanded off flush and does not need to be trimmed.

Using 35mm european style hinge mounts on the doors (and dressing the front of the door panels with narrow oak trim strips) makes for some handsome doors. Anyway, I do get lots of compliments from folks who somehow do not believe that I made these cabinets all by myself!!

Since I have a large stack of red oak, courtesy of a tornado a few years ago and a friend with a sawmill, it's actually cheaper for me to build with solid wood; at least until my current supply runs out, that is. But I prefer to make cabinets out of plywood (except for face frames & door frames) because its simpler and faster than gluing up large panels from solid wood. I can't spend all my free time in the shop, unfortunately. I find building with plywood is still satisfying, and that's what I'm in it for.

Mostley drawer bottoms, also the bottom of a baby cradle out of 3/4 Baltic Birch. Used a clear water based finish, several coats as I remember, thinking about nighttime accidents leaking thru the pad. Worked great and about to be used on another grandchild.

I agree with PDX Bob for me it is mainly a function of saving rare wood by use of veneer panels. Also because I am a pure amateur my mistakes alone could cost us a giant redwood if I used pure hardwood.

Plywood is fine, if you can get good quality, just like any other type of wood. I just cant stand particle board. thats a no no for me.

Log in or create an account to post a comment.

Sign up Log in